50%

of our global bottling

operations´ energy

requirements come

from clean sources

Consistent

50%

of our global bottling

operations´ energy

requirements come

from clean sources

Consistent

Consistent

Operating

model transformation

Consistent with our strategic framework, we continue to transform our operating models to achieve more competitive advantages creating the next generation of strategic capabilities in order to strengthen our value chain. We are further reinforcing our relationships with the communities with which we interact, contributing to our ability to serve the marketplace while enhancing our social license to operate. Overall, this is enabling us to become a fitter organization with the ability to adapt to ever-changing environments and generate sustainable growth.

50%

of our global bottling

operations´ energy

requirements come

from clean sources

Sustainable operations

At Coca-Cola FEMSA, we ensure sustainability is fully embedded throughout our day-to-day business operations. As a driver behind our strategic business decisions, our operations are firmly committed to generating sustainable economic, social, and environmental value.

Digitally Driven Operating Models

We are accelerating our digitally driven business transformation throughout our value chain—developing and deploying a demand-driven, end-to-end strategy, encompassing our digital manufacturing, distribution, and commercial models. As a result, we are creating a stronger, more agile, and flexible organization, enabled with the right capabilities to drive our competitiveness, proactively address evolving industry challenges, and capitalize on arising market opportunities.

Our commercial strategy aims to create and satisfy consumer demand for our products whenever, wherever, and however they want them. Through a deep understanding of our shoppers and consumers, our demand-driven KOFmmercial Digital Platform (KDP) is devoted to serving our clients and consumers across the traditional trade, modern trade, aggregators, and direct-to-consumer channels. This platform is based on three main pillars:

Built on advanced descriptive, predictive, and prescriptive analytics, our comprehensive KDP platform enables the development of the right operating models—coupled with the  creation of next-generation capabilities—for our four main sales channels.

creation of next-generation capabilities—for our four main sales channels.

During 2018, we fully deployed our marketing and sales analytical capabilities in Mexico and Colombia. Based on internal and external data, we redefined our pricing strategy, optimized the effectiveness of our trade promotion spending—yielding an incremental improvement in our return on investment—and designed and deployed segmented customer initiatives based on shoppers’ insights. Through our dynamic initiative management, we communicated these initiatives to our sales force team’s mobile, hand-held Sales Force Automation (SFA) devices.

With Victoria, our machine learning prescriptive analytical engine, we will considerably improve the accuracy of our demand forecasting thanks to our capacity to continuously learn what’s happening in our markets from a variety of different sources. In Mexico, where Victoria has been learning about the market for over six months, we are already improving our demand forecast accuracy by 5% over our current tools. Through Victoria’s high accuracy demand forecast, we will open up numerous opportunities to not only drive per capita demand, but also plan supply based on demand, generating significant inventory and transport savings.

We fully deployed our Dynamic Initiative Management (DIM) capabilities, utilizing our next-generation Customer Relationship Management (CRM) platform, across Mexico, Brazil, Colombia, and Argentina in 2018. With DIM, every month we identify, prioritize, and communicate more than 5 million targeted customer initiatives in Mexico, almost 2 million in Brazil, nearly 300 thousand in Colombia, and approximately 275 thousand in Argentina to our sales force in the traditional sales channel. Importantly, we measure the effectiveness of our initiatives every week and, thereby, accelerate our ability to react to market opportunities from a month to three days. Consequently, we enable our sales force to maximize the value of their customer visits and interactions, enhance our point-of-sale execution, and achieve better resource allocation in the market.

By year-end 2018, we completed the rollout of our Sales Force Automation (SFA) solution in eight countries, covering 7,600 pre-sale routes. This user-centric mobile solution empowers our sales force with best-in-class hand-held functionalities, including faster order entry, a two-way targeted initiatives module, dashboards, and 360° customer data.

We developed and deployed a best-in-class operating model to serve Brazil’s modern trade channel. This new model features end-to-end analytics, end-to-end client collaboration, and Omni-modal point-of-sale execution. Achieving historic market share, this model enabled us to reach more than 70% of the modern trade channel in São Paulo, Brazil.

Moreover, we continued the deployment of our Digital Distribution platform. This platform not only offers improved customer satisfaction, but also delivers increased resource optimization and enhanced driver safety. We also completed the implementation of our KOF Logistics Services’ (KLS) Supply Chain Planning model in all of our operations. Through this end-to-end supply chain model, we enhance our customer service, while optimizing our costs and capital allocation, through: 1) standardized strategic, tactical, and operating processes; 2) cutting-edge technological tools; and 3) enhanced centralized organizational capabilities. We further continued to benefit from warehouse optimization, particularly our implementation of voice picking technology. Importantly, we collaborated with our Commercial Center of Excellence to define our new Secondary Distribution Evolution Strategy, an end-to-end distribution model designed to enable flexibility and satisfy customer service needs.

Furthermore, we transformed and merged the core elements of our modular Manufacturing Management Model into our end-to-end Digital Manufacturing 2.0 platform. This end-to-end platform is currently comprised of our Manufacturing Execution System (MES), Statistical Process Control (SPC), Centralized Plant Maintenance Planning, and Advanced Analytics, including data science, process modeling, and failure prediction. Through our MES + SPC platform, we digitalize all of our manufacturing processes to enable better-informed decision-making, enhanced efficiency, and improved productivity. Moreover, our Centralized Plant Maintenance Planning model consolidates our manufacturing plants’ maintenance planning and budgeting at the country level. Beyond the design and development of our digital manufacturing platform, we continued the implementation of our Plant Operating Model in a total of 69 bottling lines by year-end 2018—achieving increased efficiency of 2% year over year.

We communicate

~7.5

million targeted customer

initiatives per month

We increased

2%

our operating efficiency

year over year

We finished the deployment of our Digital Distribution platform, including our web-based app, mobile delivery devices, and vehicle telemetry equipment, across our Mexican and Brazilian operations’ secondary distribution fleet—reaching 4,500 and 2,500 routes, respectively. Among its many benefits, we enjoy the capability to identify and correct operational and service deviations in our distribution route execution versus our route plan. This equipment also enables us to analyze our route performance patterns in order to identify an optimal combination of variables to improve our route planning process.

After Mexico and Colombia last year, we completed the implementation of our KLS Supply Chain Planning model across all of our plants, distribution centers, and long-haul distribution fleet in Argentina, Central America, and Brazil during 2018. We also provided more than 200 planners on our logistics team with over 10,000 hours of training. As a result of this model, we have already generated production, warehousing, and transportation cost savings of over US$15 million across these operations.

We continued to capitalize on warehouse optimization, leveraging our implementation of voice picking technology at our three main distribution centers in Brazil, Mexico, and Colombia. With this tool, we improve the efficiency and accuracy of our product picking and loading processes. We also deployed our truckload optimizer at 80% of our distribution centers in Brazil. Through these initiatives, we optimize our storage, handling, and labor costs while minimizing our delivery trucks’ time spent at our distribution centers.

We deployed our MES + SPC platform across our manufacturing processes in Mexico, Brazil, Colombia and Argentina. In 2018, we deployed our MES platform’s real-time monitoring of our utilities process—covering all aspects of our plant’s power needs—in 13 of our bottling plants across 4 countries, while implementing SPC in 45 bottling plants throughout our operations.

We fully implemented Centralized Plant Maintenance Planning throughout our 40 bottling plants in Mexico, Brazil, Colombia, Argentina, and Venezuela. This innovative model improves our operating efficiency by reducing downtime.

We leveraged Advanced Analytics to improve the performance of various manufacturing facilities. For example, at our bottling plant in Villahermosa, Mexico, we employed an advanced analytical tool to significantly reduce scuffing and, increase life of returnable PET bottles. Moreover, at our wastewater treatment plant in Apizaco, Mexico, we designed and deployed an advanced analytical methodology that controls multiple parameters to reduce substantially this facility’s energy consumption.

“We finished the deployment of our Digital Distribution platform, including our web-based app, mobile delivery devices, and vehicle telemetry equipment, across our Mexican and Brazilian operations’ secondary distribution fleet.”

We look to capture the analytical insights we gain from our comprehensive KDP platform to develop and deploy tailored direct and indirect route-to-market (RTM) models that maximize and capture customer value creation, while optimizing our cost to serve. Utilizing our advanced analytics capabilities, we will build trust-based partnerships with our clients, identify new ways to reach our customers, shoppers, and consumers, and digitalize our route-to-market process.

“In Mexico, we employed an advanced analytical tool to significantly reduce scuffing and, increase life of returnable PET bottles.”

In all of our Colombian and more than half of our Mexican operations, we have deployed our market-driven RTM 3.0 to serve the needs of our strategic customer segments across the traditional sales channel. Through this model, we allocate the appropriate resources—from the sales personnel who interact with our clients, to the frequency of their visits, to the quantity of our targeted initiatives, to our level of marketing support—in order to capture the most value from each client segment, large and small.

Through “Coca‑Cola en tu Hogar,” we successfully converted a third of our jug water routes to direct home delivery routes, offering those households our full portfolio of products from the convenience of their own homes. Consequently, we not only expanded the coverage of our portfolio, but also increased the productivity and profitability of those routes, while continuously improving the way we serve the market.

In Brazil, we implemented mobile technology such as the WhatsApp mobile communications model to complement our high-volume customers’ daily visits with related messages, including targeted initiatives. Our mobile apps focused heavily on recurring service orders, and through our collaboration with Rappi and iFood, we designed cross-category combinations, particularly ready-to-eat meals to promote and sample new products. We also developed a Credit Policy tailored to suit the needs of our low-volume customers, who receive face-to-face visits every 15 days, to expand their inventories and reduce their risk of stock outs.

We fully implemented our pre-sale platform in Guatemala. This platform enables our sales people to focus on stimulating and satisfying customer demand prior to delivery and to serve our clients’ needs better by loading their desired mix of products on our trucks. Through our pre-sale system, our sales people provide additional merchandizing and promotional services during their regular customer visits and, thereby, enhance our picture of success, while improving our product sales and profitability.

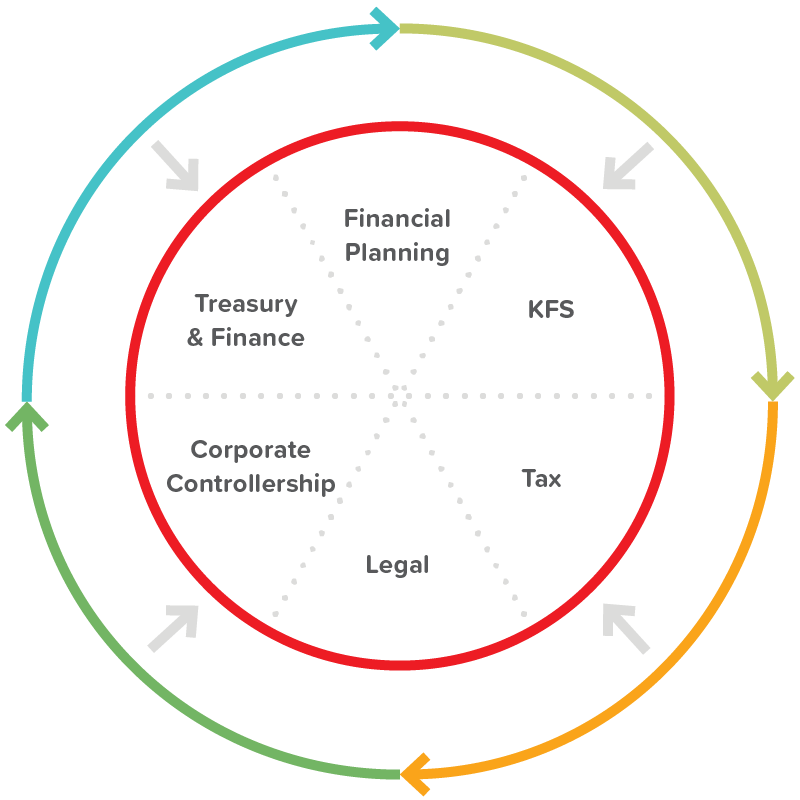

KOF Global Business Services model is designed to better support and enable our company’s global and local strategy. Consistent with our business strategy, objectives, guidelines, and requisite accounting and financial results, three specialized entities we established in the Finance area, our Corporate Experts team, KOF Financial Services (KFS), and Region/Country Finance team who work collaboratively to give on-field support focused on providing the rules of engagement and financial services to serve our internal and external clients and ensure our strategic objectives. Through our Transformation Framework, we enable an efficient, technology-supported, and harmonious Administrative & Financial (A&F) Service Model.

Moreover, with the implementation of KOF People Services in our Mexico operation and corporate headquarters, we have consolidated human resources services, including updating personal data, payroll, talent platform, requests for letters, vacations, savings and benefits, and paid and unpaid leaves, for all of our workplaces through kiosks and a mobile app, promoting self-service at all organizational levels.

“KOF Global Business Services model is designed to better support and enable our company’s global and local strategy.”

Transformation Framework

At Coca-Cola FEMSA, we embrace a holistic approach to sustainable development by ensuring sustainability is fully embedded throughout our day-to-day business operations. To this end, we strategically, efficiently, and responsibly address our operations’ environmental and social challenges across our value chain—from clean energy to responsible waste management, community development, and safety.

We strive for energy efficiency across our value chain. We further integrate clean and renewable sources of energy and technologies to reduce our carbon emissions—thus contributing to climate change mitigation.

Consequently, our operations’ energy consumption focuses on a comprehensive strategy that encompasses our manufacturing operations. Consistent with this strategy, we have defined the following 2020 goals:

OUR 2020 GOALS

Reduce the carbon footprint

of our value chain by 20% against our 2010 baseline.

Supply 85% of the energy we use for our manufacturing in Mexico from clean sources.

“At Coca-Cola FEMSA, we embrace a holistic approach by ensuring sustainability is fully embedded throughout our day-to-day business operations.”

Science based targets initiative: transition to the low-carbon economy

Coca‑Cola FEMSA joined over 500 international companies in the Science Based Targets initiative, which aims to mobilize companies to set science-based greenhouse gas emissions targets and boost their competitive advantage in the transition to the low-carbon economy. The initiative is a collaboration between CDP (formerly the Carbon Disclosure Project), the United Nations Global Compact, World Resources Institute, the World Wide Fund for Nature, and one of the We Mean Business Coalition commitments.

We have reduced

40%

our Carbon emissions

from 2010 through 2018

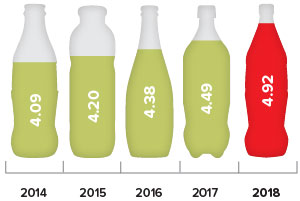

Our aim is to improve the energy efficiency of our manufacturing operations, while simultaneously reducing our greenhouse gas emissions. To this end, we managed to increase our energy efficiency by 33% from 2010 to 2018.

To improve our plants’ energy efficiency, we have implemented multiple strategic initiatives:

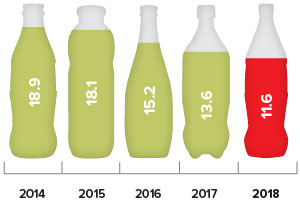

From 2010 through 2018, we achieved a 40% decrease in our manufacturing operations CO2(eq) emissions, reaching 11.62 grams of CO2(eq) per liter of beverage produced in 2018.

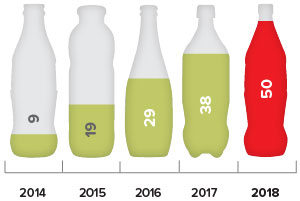

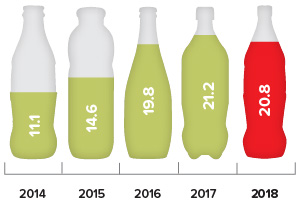

By 2020, we look to satisfy 85% of our Mexican manufacturing operations’ energy requirements with clean energy. By year-end 2018, we achieved 51.5% coverage of our Mexican bottling operations’ power needs. Overall, we accomplished 50% coverage of our global bottling operations’ energy requirements, up more than fivefold from 9% in 2014. We use clean sources of energy for our manufacturing operations in Mexico, Brazil, Colombia, Argentina, and Panama.

For the year, we reduced our energy consumption by 10%, resulting in the following total savings:

US$5.62 million – total energy savings

“50% of our operations electric power comes from clean sources, in Mexico, Brazil, Colombia, Argentina, and Panama.”

Water is an essential ingredient in the production of our beverages. Consequently, we are committed to ensuring the efficient use and conservation of this natural resource for the benefit of our company, our communities, and our planet.

Consistent with this commitment, we have established a comprehensive water strategy, founded on three pillars:

OUR 2020 GOALS

Increase our efficiency in water usage to 1.5 Liters of water per liter of beverage produced.

Return to our communities and their environment the same amount of water used in our beverages.

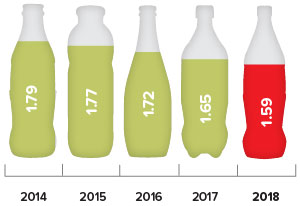

As a beverage bottler, efficient water management is essential to our business, our communities, and our planet. Our goal is to improve our water use ratio to 1.5 liters of water per liter of beverage produced by 2020. For 2018, we achieved 1.59 liters of water per liter of beverage produced—an 19% improvement in our water use ratio from our 2010 baseline. Moreover, our water efficiency initiatives and projects generated savings of US$1.38 million in 2018.

Through our Top 20 Water Saving Initiatives program, we foster efficient water consumption across all of our plants. To this end, we registered significant progress across our operations, focusing on 20 key measures—from our detection and elimination of leaks to optimal water use in our plants to our water recovery systems.

“100% of the water we discharge from our manufacturing operations is sent to wastewater treatment plants, which ensure sufficient quality to foster aquatic life.”

In collaboration with the FEMSA Foundation, we carry out projects designed to improve communities’ quality of life by helping to provide them with safe water, improved sanitation, and hygiene education. While the Foundation intervenes considerably at the outset of each project, all of these initiatives utilize the necessary elements to enable communities to adopt them in a sustainable way—enduring over the long term.

Aligned with the United Nations’ Sustainable Development Goals, we recognize that water is an important and essential natural resource. Accordingly, we join efforts to provide access to potable and affordable water, as well as to protect and recover water-related ecosystems.

We are committed to returning the water we use in our processes by replenishing and conserving watersheds to ensure water balance in the communities where we interact. To this end, our goal is to reduce our water consumption and to return to the environment and our communities the same amount of water used to produce our beverages by 2020. Consistent with our commitment, we currently give back to the environment more than 100% of the water we use in the production of our beverages in Brazil, Central America, Colombia, and Mexico.

In light of the substantial scope, importance, and complexity of water conservation and replenishment, we work to strengthen water funds and conserve water basins through sustainable initiatives involving partnerships with several stakeholders. For example, through the Latin American Water Funds Alliance—comprised of the Nature Conservancy, the FEMSA Foundation, the Inter-American Development Bank (IDB), and the Global Environmental Fund—we jointly seek to offer hydrological safety in the region, ensuring sustainable access to a sufficient quantity and quality of water to sustain human life and socioeconomic development.

To date, the Alliance has developed 24 water funds. Of these funds, five are in countries where we operate—Brazil, Colombia, Costa Rica, Guatemala, and Mexico. As a result of this partnership, the Alliance has worked to directly benefiting 8,600 people in areas near the water basins through job creation and capabilities training since the projects began.

At Coca‑Cola FEMSA, we strive to mitigate the environmental impact of our operations’ processes. Over the past years, we have led the way in the promotion of a culture of waste management throughout all of our operations and our value chain, focusing on the following strategic priorities:

KOF Waste Management Strategy

OUR 2020 GOALS

To recycle at least 90% of the waste we generate in every one of our bottling plants.

To include 25% of recycled materials in our pet packaging.

Within the beverage industry, our product packaging is mainly comprised of PET, glass, and aluminum, which preparation and post-consumption handling can impact the environment and communities. Accordingly, we are committed to efficiently using our packaging materials, redesigning our packaging’s components to achieve 100% recyclability and include recycled resin.

To this end, our goal is to incorporate 25% recycled material into all of our PET packages by 2020. In 2018, we successfully integrated close to 21% of recycled resin into the production of all of our PET presentations. Notably, we provide our consumers and clients with a water bottle made of 100% recycled resin for all of our one-way PET presentations of Ciel brand water in Mexico.

Consistent with our efficient resource management and optimization of our packaging materials, we continued to deploy a wide-ranging light-weighting strategy for our operations’ PET presentations and caps. We also launched a new initiative to reduce the size of our labels without sacrificing the nutritional information that we provide to our consumers.

Thanks to our light-weighting initiatives, we have saved more than 25 thousand tons of PET resin since 2011. In addition, through our efficient resource management and packaging optimization, we generated savings of approximately US$14.6 million in 2018.

By joining efforts, we multiply the effects of our actions. Accordingly, we partner with communities, authorities, and NGOs on different initiatives to raise awareness of post-consumer waste management, carry out collection and recycling programs within our communities, and educate and inform consumers on the proper disposal and handling of the waste generated from our products, including water body litter prevention, debris collection, and beach cleanups.

For over 16 years, we have collaborated with other food and beverage companies through ECOCE, a Mexican civil association that promotes the collection of waste, the creation of a national market for recycling, and the development of recycling programs. Thanks to this collaborative effort, in 2018, ECOCE collected 58% of the total PET waste in Mexico.

Furthermore, we are leaders in PET bottle-to-bottle recycling in Latin America. In 2005, we joined efforts in Mexico to operate the first Food Grade PET Recycling Plant in Latin America, called IMER (Industria Mexicana de Reciclaje or Mexican Recycling Industry). In 2018, this plant, recycled 11,422 tons of PET.

Overall, in 2018, we utilized a total of almost 63,853 tons of recycled materials in our plants in Argentina, Brazil, Central America, Colombia, and Mexico. As a result of these efforts, we have used more than 273,000 tons of recycled PET since 2010.

In 2018, 17 of our bottling plants in Mexico certified as Zero Waste. Designed for our Mexico operations, this initiative establishes specific measures to improve waste management, disposal, and repurposing—resulting in improved waste efficiency per liter of beverage produced.

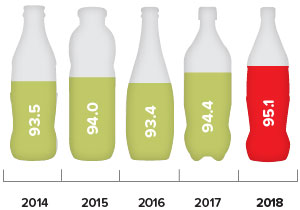

By 2020, we aim to recycle at least 90% of our waste in each of our bottling plants. At year-end 2018, 93% of our plants successfully achieved this goal. Importantly, in Mexico, our plants recycled 100% of the waste generated in our production processes. Overall, we recycled 95% or approximately 134,000 tons of manufacturing waste generated.

Currently, 17 of our plants in Mexico have obtained Clean Industry certification from the Federal Environmental Protection Agency (PROFEPA). Moreover, in 2018, 36 of our distribution centers in Mexico received air quality certifications from PROFEPA, the State of Mexico’s Environmental Agency, Mexico City’s Secretary of the Environment (SEDEMA). These and other recognitions confirm our commitment to the environment and overall sustainability.

To this end, we diligently work to ensure our processes comply with the highest national and international standards and with all applicable laws, avoiding sanctions and fines pertaining to environmental issues, while reaffirming our commitment to efficient operational processes, environmental performance, and competitiveness.

“In 2018, 17 of our bottling plants in Mexico certified as Zero Waste.”

Aligning our efforts with The Coca‑Cola Company, we embrace their “World Without Waste” global initiative’s 2030 vision:

This year, we signed onto The New Plastics Economy Global Commitment. Led by the Ellen MacArthur Foundation with support from the World Wide Fund for Nature, the World Economic Forum, and The Consumer Goods Forum, among others, the Global Commitment mobilizes the public and private sectors to achieve its vision for a circular economy for plastic.

The following table concentrates the historical performance of our most important environmental indicators.

| Performance Indicator | Unit of Measure | 2010 | 2014 | 2015 | 2016 | 2017 | 2018 |

|---|---|---|---|---|---|---|---|

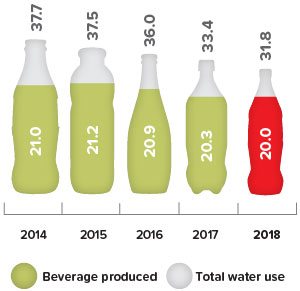

| Beverage produced | Billion liters | 20.0 | 21.0 | 21.2 | 21.0 | 20.3 | 20.0 |

| Water use1 | Billion liters | 39.1 | 37.7 | 37.5 | 36.0 | 33.4 | 31.8 |

| From municipal sources | Billion liters | - | - | - | - | 8.4 | 9.4 |

| From superficial sources and rain | Billion liters | - | - | - | - | 0.7 | 0.5 |

| From underground sources | Billion liters | - | - | - | - | 24.4 | 21.9 |

| Water efficiency | Liters of water used per liter of beverage produced | 1.96 | 1.79 | 1.77 | 1.72 | 1.65 | 1.59 |

| Total PET used | Thousand tonnes | 222.7 | 288.6 | 338.3 | 315.6 | 294.9 | 305.8 |

| PET virgin resin used | Thousand tonnes | 213.1 | 256.6 | 288.9 | 253.0 | 232.3 | 241.9 |

| Recycled PET use | Thousand tonnes | 9.6 | 19.4 | 33.7 | 47.4 | 59.2 | 63.9 |

| Recycled materials used in PET packaging | Percentage of total PET used | 4% | 11% | 15% | 20% | 21% | 21% |

| Waste generated | Thousand tonnes | 179.0 | 189.0 | 174.0 | 174.0 | 152.0 | 141.6 |

| Waste recycled | Thousand tonnes | 153.0 | 177.0 | 164.0 | 163.0 | 144.0 | 134.6 |

| Waste recycled | Percentage of total waste generated | 86% | 93% | 94% | 93% | 94% | 95% |

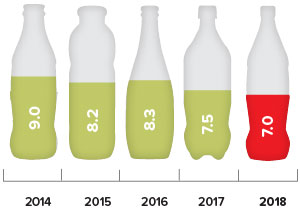

| Waste efficiency | grams of waste generated per liter of beverage produced | 8.9 | 9.0 | 8,2 | 8.3 | 7.5 | 7.1 |

| Total energy use2 | Million Megajoules | 5418.0 | 5147.0 | 5048.0 | 4862.0 | 4514.0 | 4069.5 |

| Energy from fuel use | Million Megajoules | - | - | - | - | 2382.0 | 2021.4 |

| Electricity from clean sources | Million Megajoules | - | - | - | - | 810.2 | 1024.4 |

| Other electricity | Million Megajoules | - | - | - | - | 1321.8 | 1023.8 |

| Energy efficiency2 | Liters of beverage produced per Megajoule of energy used | 3.7 | 4.1 | 4.2 | 4.4 | 4.5 | 4.9 |

| Global clean energy use | Percentage of total energy use | 0% | 9% | 19% | 29% | 38% | 50% |

| Clean energy use in Mexico | Percentage of total energy use | 0% | 26% | 30% | 46% | 57% | 52% |

| Greenhouse Gas Emissions efficiency3 | Grams of CO2e per liter of beverage produced | 21.1 | 18.9 | 18.1 | 15.3 | 13.6 | 11.6 |

| 1 | Includes the water used in our manufacturing facilities obtained through direct measurment and internal management processes. |

| 2 | Includes all energy use in our manufacturing facilities. Considering: Diesel, Fueloil, Natural and LP Gas, Electricity from clean sources and other electricity. |

| 3 | Includes Scope 1 and Scope 2 CO2e (CO2, CH4, NO) emissions in our manufacturing facilities obtained through direct measurement and internal management processes. Emission factors were considered from the following: Fuel: IPCC Fifth Assesment Report 100 year time horizon Electricity: World Resources Institute. Purchase electricity tool. Version 4.8 and Mexican Energy Regulation Comission (CRE) emission factor 2017 |

We view and understand safety as a principle action and key pillar of our business. Consequently, we are committed to inspiring a safety culture—valued for improving the welfare of our employees, business partners, contractors, and their families, together with the communities where we operate.

OUR 2020 GOALS

To reach a Lost Time Incident Rate (LTIR)1 of 0.5 per 100 employees and a Total Incident Rate (TIR)2 of 1.5.

| 1 | (# Accidents x 200,000)/Hours Worked. |

| 2 | (# Total Reportable Incidents x 200,000)/Hours Worked. The factor of 200,000 is obtained from the estimated hours worked by 100 employees over 50 weeks at 40 hours per week. This factor allows for a comparison of the indicators as a proportionate rate. |

Overall, we aim to achieve zero work-related injuries and illnesses among our employees, contractors, and communities by ensuring the safety of our workplace through minimizing safety risks, eliminating incidents that could arise in our work centers, and developing safety capabilities across our organization. Until we achieve our vision of zero incidents, we accelerated the annual reduction of our incident rates to 10% and the achievement of world-class indicators aligned with our 2020 – 2022 safety goals.

To this end, we established KOF Safety Council, representing the 10 countries where we operate, to define a transformational safety strategy and initiatives for our entire company. In 2018, the Council validated and complemented our four-pillar Safety Strategy.

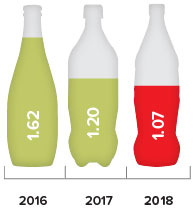

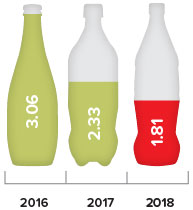

As a result of our strategic initiatives, we reported a Lost Time Incident Rate (LTIR) of 1.07 in 2018, a 12% decrease compared with 2017 and a 69% reduction compared with 2014. They also contributed to a 16% reduction in our Lost Time Incident Severity Rate (LTISR), from 26.97 in 2017 to 22.68 in 2018. We further achieved a Total Incident Rate (TIR) of 1.81, a 22% decrease versus 2017.

We continued our KOF Safety Cultural Transformation program that we started two years ago, aligning the model and the plan for each operation. Through this transformational journey, we inspire a culture of safety by addressing our people’s beliefs about safety and managing their behavioral consequences across our organization. During 2018, we connected more than 35,000 employees and 200 work centers by forming 150 cultural committees, carrying out more than 500 activities, and conducting more than 50 leadership workshops.

12%

reduction of our

Lost Time Incident Rate

year over year

We recognize that some of our business activities can be dangerous and, consequently, can cause damage to our people, facilities, and business if we do not manage them properly. Therefore, we have established prevention measures and standards to ensure that safety is a top priority, improve our processes, and define ways to manage key risks in a standardized, systematic manner—ensuring that our employees, contractors, and third parties do not experience incidents during their work activities.

During 2018, we developed and implemented processes, programs, and digital technologies that enabled us to manage more effectively the critical activities of our Top Five Initiative and Key Risks Standardization across our production and distribution facilities.

We launched the first stage of our School of Safety at the beginning of 2018. This three-year, 12 technical module program is initially focused on providing the leadership, technical, and functional skills to the professionals who are in charge of our Safety functions, so they become multipliers of knowledge throughout our organization. Our business units’ training programs include our Colombia operation’s Truck Safety School induction and our Brazil and Mexico operations’ Drivers School.

“During 2018, we developed and implemented processes, programs, and digital technologies that enabled us to manage more effectively the critical activities.”

As part of our Safety Strategy and Digital Supply Chain Strategy, we installed telemetry systems in our Mexican and Brazilian operations’ fleets to monitor and improve the behavior and performance of our drivers. We also included devices to ensure safe reverse maneuvers for 100% of our secondary distribution fleet across Mexico. We further fostered the development of competencies through road simulators and virtual reality tools in our Mexico and Brazil operations that enable us to accelerate learning processes and develop positive driving capabilities.

OUR 2020 GOALS

To achieve a 50% crash rate reduction from our 2016 baseline.

In 2018, we achieved a

60%

crash rate reduction from our

2016 baseline and accomplished

our 2020 goal

We have been implementing our companywide Road Safety Standard throughout the course of 2018. Based on three key elements—People, Organization, and Vehicles—this standard has significantly improved our road safety by reducing the number of accidents within our organization. To support this road safety strategy, our business units have developed innovative initiatives that have accelerated our positive performance in this critical area, focused on developing our drivers’ capabilities and organizational processes while implementing monitoring and risk management technology.

Last year, we deployed mandatory safety specifications for all new secondary distribution trucks that we purchased. These specifications include:

During 2018, we implemented these mandatory safety specifications for 230 new delivery trucks that we bought in Mexico.

In 2018, our Brazilian team developed an app for Behavior-Based Safety Programs to help directors and leadership teams identify, track and follow up on actions that might pose a safety opportunity in their operations, allowing them to create a safety culture based on prevention and risk mitigation.

At Coca-Cola FEMSA, we firmly believe that all accidents are preventable. Accordingly, we continually research, analyze, and identify the measures required to reduce the number of injuries resulting from our operations.

For 2018, we reduced our total fatalities by 29%. This data includes our manufacturing, distribution, and trading operations that impact both our employees and our communities. Importantly, 95% of our operations did not have fatalities; however, the remaining 5% is still an unacceptable number. Although we made positive progress to decrease the number of fatalities for which our company is accountable to six from nine last year, the loss of any individual associated with our operations is unacceptable, so we continue to work hard to achieve our goal of zero injuries and fatalities.

Through our Sustainable Mobility strategy, we aim to reduce the impact of our fleet—including our primary and secondary distribution trucks—and to position ourselves as the industry leader in Latin America in terms of vehicle efficiency, environmental stewardship, and safety.

We are executing route optimization strategies to maximize our overall vehicle efficiency. With the complete rollout of our KOF Digital Distribution platform in Mexico and Brazil, we have installed telemetry equipment on 100% our secondary distribution fleet. Thanks to our trucks’ telemetry data—combined with the functionality of our mobile delivery devices—we enjoy the capability to identify and correct deviations in our distribution route execution versus our route plan. This equipment also enables us to analyze our route execution patterns in order to identify an optimal combination of variables to improve our route planning process. As a result, we optimize our fleet’s usage, minimizing our vehicles’ downtime while maximizing our vehicles’ uptime. Thanks to our telemetry equipment, we also significantly reduced our fuel consumption by more than 1.2 million liters for the year.

“We have installed telemetry equipment on 100% of our secondary distribution fleet in Mexico and Brazil.”

Moreover, with our deployment of dynamic routing across our secondary distribution fleet in Brazil, Colombia, and Argentina, we enjoy the flexibility to plan our vehicles’ routes every day, thereby optimizing our available fleet resources and our distances traveled to serve our customers.

Additionally, we leveraged our secondary fleet substitution program in Mexico and Brazil, where we maintain our largest volume of delivery trucks. Over the past three years, we have substituted more than 600 trucks with vehicles that meet higher emission standards. Thanks to this program, we not only significantly reduce our fuel consumption, emissions, and maintenance costs, but also reinforce our commitment to eco-efficiency with local environmental authorities.

In the Valley of Mexico, we continued to work closely with local governmental authorities to earn certification for 1,400 of our trucks under the self-regulation program. Pursuant to this voluntary program, we commit to minimize our local delivery fleet’s emissions through key initiatives, including our efficient maintenance process and ongoing fleet substitution program. Among other benefits, local authorities allow us to continually operate our complete secondary distribution fleet every day—fostering our social license to operate.

“With our deployment of dynamic routing across our secondary distribution fleet in Brazil, Colombia, and Argentina, we enjoy the flexibility to plan our vehicles’ routes every day.”

Environmental excellence

In recognition of our CO2e emissions reduction, we earned the Environmental Excellence Award from Mexico’s Federal Agency of Environmental Protection (PROFEPA). Moreover, for voluntary efforts to reduce our vehicles’ emissions, we earned the Clean Transportation Award from Mexico’s ministries of Environment and Natural Resources (SEMARNAT) and Communications and Transportation (SCT) for the eighth consecutive year.

We work closely with our communities to strengthen and consolidate positive relationships with our communities; identifying and developing shared opportunities for our company and communities’ sustainable development.

At Coca-Cola FEMSA, we work with our suppliers to reduce the environmental and social impacts generated by our commercial interactions and thus improve the conditions of our supply chain. In this way, we not only minimize negative impacts, but also raise standards in key business areas, increase labor efficiency, preserve environmental capital, and reduce risks and costs for all those involved throughout the value chain.

As part of our company’s sustainable sourcing mandate, in conjunction with our defined strategic initiatives, each supplier cooperates to minimize their social and environmental risks over which we have no direct control and which cause impacts throughout our supply chain on a daily basis. The general guidelines that we use to make this happen are:

These principles reflect the standards that guide our daily activities to ensure we provide responsible workplaces that protect human rights and comply with environmental laws. Founded on these principles, we follow a comprehensive five-step Sustainable Sourcing Strategy:

Year after year, our company uses a proprietary tool to determine which suppliers from the countries that we have evaluated are candidates for a risk mitigation process. Suppliers are prioritized by taking into account factors such as expenditure, environmental, social, and ethical impacts for each product category, dependability, brand association, and operational criticality. After this analysis, a list of suppliers that must enter the evaluation process is generated.

“At Coca-Cola FEMSA, we work with our suppliers to reduce the environmental and social impacts generated by our commercial interactions and thus improve the conditions of our value chain.”

Through this step, we include FEMSA’s Supplier Guiding Principles in our supplier contracts and requests for information, give general guidelines for assessment procedures, and provide training for sourcing and purchasing employees.

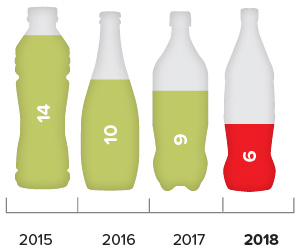

At Coca-Cola FEMSA, we assess our suppliers continuously through our Sustainable Sourcing System, ensuring that they are aligned with our company’s operating principles and values. Carried out online, this assessment focuses on four main areas: Social/Labor Rights; Environment; Ethics and Values; and Community. To ensure the process’ transparency, a third party reviews and verifies the information, and we then provide feedback and create action plans to encourage supplier development, ethics, and sustainability. All of our suppliers with low scores are audited at their facilities and evaluated periodically to encourage their continuous improvement. This year, we conducted 400 supplier evaluations based on FEMSA’s Supplier Guiding Principles, performing these evaluations for the first time in Argentina and Panama. Since 2015, we have carried out 1,471 evaluations under these principles.

| Suppliers assessed under The Coca‑Cola Company guiding principles |

||||||||

|---|---|---|---|---|---|---|---|---|

| COUNTRY | 2015 | 2016 | 2017 | 2018 | ||||

| Mexico | 33 | 52 | 40 | 59 | ||||

| Costa Rica | 2 | 3 | 7 | 0 | ||||

| Guatemala | 3 | 5 | 8 | 7 | ||||

| Nicaragua | 0 | 1 | 0 | 0 | ||||

| Panama | 1 | 0 | 3 | 3 | ||||

| Argentina | 5 | 11 | 19 | 10 | ||||

| Brazil | 54 | 47 | 102 | 51 | ||||

| Colombia | 8 | 7 | 18 | 11 | ||||

| Venezuela | 1 | 0 | 0 | 0 | ||||

| Total | 107 | 126 | 197 | 141 | ||||

Since 2015,

we have carried out

1,471

evaluations under FEMSA’s

Supplier Guiding Principles

Consistent with this strategy, The Coca-Cola Company assesses and ensures compliance with its guiding principles and sustainability standards for specific categories of strategic suppliers; we only work with suppliers approved by TCCC in those categories. In 2018, TCCC carried out 141 evaluations of suppliers aligned with their supplier guidelines.

| Suppliers assessed under FEMSA guiding principles |

||||||||

|---|---|---|---|---|---|---|---|---|

| COUNTRY | 2015 | 2016 | 2017 | 2018 | ||||

| Mexico | 100 | 198 | 245 | 172 | ||||

| Costa Rica | 30 | 120 | 106 | 34 | ||||

| Guatemala | – | – | 49 | 34 | ||||

| Nicaragua | – | 84 | 94 | 27 | ||||

| Brazil | – | – | 45 | 66 | ||||

| Panama | – | – | – | 36 | ||||

| Argentina | – | – | – | 31 | ||||

| Total | 130 | 402 | 539 | 400 | ||||

In addition to these assessments, Coca-Cola FEMSA is one of the few companies that promoted the application of these assessments to our Tier 2 suppliers or the suppliers of our suppliers. Currently, our strategic suppliers are applying the same risk assessment and mitigation mechanisms within their own value chain. This ensures that the knowledge and the drive for greater sustainability not only remains within our circle of influence, but also extends to all of those who participate in supplying our raw materials, inputs, and services.

To strengthen our suppliers’ business capabilities, we provide them with access to training and growth initiatives on topics such as finance, marketing, and human resources, among others. We also support their growth and build their business skills, improve their companies, and develop high quality products aligned with our principles and values.

In collaboration with the Mexican Center for Competitiveness (Centro Mexicano de Competitividad), we carry out a Comprehensive Supplier Development Program for strategically selected small- and medium-sized enterprises (SMEs) to improve their business capabilities. Through this program, we collaborate with suppliers to not only improve their sustainable competitiveness, but also forge stronger relationships with our company and other large companies. In 2018, 50 suppliers participated in the program, training a total of 231 suppliers from Mexico and Costa Rica over the past three years.

The good performance of our suppliers on sustainability issues is very important. Accordingly, we recognize all of those suppliers that incorporate sustainability into their own business’s DNA not only as a requirement for doing business with Coca-Cola FEMSA, but also as a competitive advantage and a means to become socially responsible. In Brazil, we conduct the Premium Suppliers program through which we recognize suppliers in the following categories:

To develop stronger relationships with our immediate communities, we encourage continuous dialogue and interaction. By systematically analyzing their particular needs, we design and deploy activities that benefit both our communities and our company. In this way, we seek to build trust and ensure the commitment of all parties involved—maintaining our social license to operate.

This not only enables us to consolidate positive relationships with our communities, but also contributes to our ability to serve the market while identifying key opportunities to collaborate with our neighbors.

OUR 2020 GOALS

To put in place a community relations plan throughout 100% of our key work centers.

“To develop stronger relationships with our immediate communities, we encourage continuous dialogue and interaction.”

To create a community relations vision that we can put it into practice in a standardized and systematic manner, we developed a management model that includes five sequential steps—which are the foundation of our Model for Addressing Risks and Relations with the Community (MARRCO).

IDENTIFY AND UNDERSTAND

Objectives, capabilities, priorities, needs, resources, and commitments of the business towards the community.

ANALYZE AND PLAN

The risks and opportunities for designing community engagement activities and programs.

AGREE AND ACT

Listen to and build with the community to set commitments and execute mutually beneficial activities and programs.

ASSESS AND MEASURE

Impact levels of the community engagement activities and programs, and of the plan’s progress.

LEARN AND IMPROVE

Strengthen the capabilities and develop abilities by identifying areas for improvement, best practices, and knowledge exchange.

BUSINESS

Identifying the impact and influence of a community in achieving business goals, considering community risks.

COMMUNITY

Identify the impact of the business strategy on the community.

OPPORTUNITIES

Finding opportunities to collaborate with the community to improve their living conditions.

During 2018, we implemented MARRCO in 20 work centers. From 2016 to date, we have implemented MARRCO in 48 work centers, including plants and distribution centers, representing 77% of our manufacturing facilities.

Based on MARRCO methodology, these work centers are designing a community engagement plan to immediately implement a series of measures, including mitigation activities to reduce our operational footprint and community programs aligned with local needs and risks. In turn, this will help us to ensure our positive coexistence and our business’ permanence at those locations.

| MARRCO locations | ||

|---|---|---|

| COUNTRY OR REGION |

WORK CENTER | |

| DISTRIBUTION CENTERS |

MANUFACTURING FACILITIES |

|

| Mexico (15) | – | Altamira, Coatepec, Cuatitlán, Cuernavaca, Ixtacomitán, Lagos de Moreno, Reyes, Morelos, Puebla, Querétaro, San Juan del Río, Tabasco, Tamaulipas, Toluca, Veracruz |

| Argentina (4) | Mega, Parral | Alcorta, Monte Grande |

| Brazil (12) | Blumenau, Jurubatuba, Santos, Sumaré, Marilia | Campo Grande, Itabirito, Jundiaí, Marilia Planta, Maringá, Porto Alegre, Antonio Carlos |

| Colombia (10) | Girardot, Monteria, Valledupar | Barranquilla, Bogotá, Bucaramanga, Calera, Cali, Medellín, Tocancipá |

| Costa Rica (2) | – | Calle Blancos, Coronado |

| Guatemala (1) | – | Guatemala |

| Nicaragua (1) | – | Managua |

| Panama (3) | Panama CEDIS | Estrella Azul, Panama |

US$3.0

million invested to foster

community development and local

environment impacts

At Coca-Cola FEMSA, we have built positive relationships with our communities by carrying out different social programs and initiatives in order to improve local living conditions from the moment we begin our operations. Recognizing the diversity of our countries and communities, we develop enriching activities aligned with their local needs.

In 2018, we carried out 179 community development interventions, to benefit our communities across the 10 countries where we operate.

Among our many different activities, our exemplary social programs and initiatives in these countries include:

BRAZIL

Edital Idéias para um Mundo Melhor

The project took place in Maringá, Itabirito, Marília, Jundiaí, Sumaré and Porto Alegre. A public call for proposals from social organizations that want to receive support or sponsorship for their project, which should be linked to the pillars of our sustainability strategy of healthy lifestyle, environment and community development. The pre-selected projects are invited to present at our facilities in the presence of a committee composed of several employees in leadership positions who jointly choose the winning project.

ARGENTINA

Canteros Alcorta Program

We rehabilitated the boulevard in front of our Alcorta plant by installing sports facilities.

COSTA RICA

Female Empowerment Project

With the participation of female entrepreneurs and neighbors from Calle Blancos, we carry out financial practices workshops to benefit their small businesses.

MEXICO

Vive Tu Parque

These parks feature an outdoor gym, sports facilities, drinking fountains, children’s games, and lights.

URUGUAY

ANIMA

We receive students so they can complete their educational process performing the tasks agreed with ANIMA teachers for their development and learning. In turn, they receive an established remuneration and a subsequent evaluation of their performance.