Driven by our obsessive focus on our consumers and customers, we are consolidating a leading total beverage portfolio with options for every consumer taste and lifestyle, while promoting healthy habits—prioritizing the safety and wellbeing of our employees, customers, consumers, and communities throughout the course of the COVID-19 pandemic.

CONSUMER-CENTRIC

PORTFOLIO

Our strategy aims to build a winning consumer-centric portfolio for every occasion by leveraging affordability to drive sustainable sparkling beverage growth; capturing new consumption occasions and preferences through portfolio innovation; and consolidating our market leadership in emerging beverage categories, such as hydration, nutrition, and energy, while exploring new categories with discipline.

Our customers and consumers are at the center of everything we do. By deeply understanding their changing tastes and buying habits, we act faster than competitors to adapt our portfolio, product promotion, and packaging to evolving consumer behavior.

By deeply understanding our shoppers and consumers’ changing tastes and buying habits, we act faster than our competitors to adapt our portfolio to satisfy their everchanging needs.

Leverage Affordability To

Drive Sustainable Sparkling

Beverage Growth

Throughout the year, affordability remained an important engine for our sparkling beverage growth. Our agile affordable packaging strategies gained even greater relevance as our cost-conscious consumers adapted their purchasing patterns and preferences across our operating countries.

Capture New Consumption

Occasions Through

Portfolio Innovation

Through ongoing portfolio innovation, we continue to focus on improving our competitive position and capturing the most value from our sparkling beverage brands by closely aligning our portfolio with consumers’ tastes and preferences. Among our initiatives, we continue to drive the development of our no- and low-sugar portfolio of sparkling beverages to satisfy and stimulate demand for our products, while adapting our portfolio to evolving consumer behavior.

Capitalize On Emerging

Beverage Categories

We continue to capture market share across emerging beverage categories—from hydration to nutrition, and energy—while exploring new categories with discipline. Among our strategies we continue to grow our innovative water portfolio to refresh and rehydrate our consumers throughout their day, while developing our broader portfolio to seize value share leadership across the still beverage category.

healthy habits

As leaders in the beverage industry, we continue to meet the changing lifestyles of our consumers and the communities we serve. Among our actions, we carry on driving the development of our low- or no-sugar portfolio across our markets ahead of consumer demand. We also strive to promote healthy habits in our communities through multi-sector coalitions and local initiatives focused on fostering healthy habits, proper nutrition, and physical activity.

Surpassing our 2020 goal by 2 million people

Prioritizing Customer & Consumer Safety

Aligned with our DNA, we obsessively focus on our customers and consumers. Accordingly, throughout the course of the COVID-19 pandemic, we continue to concentrate on their needs, their safety, and their wellbeing, providing them with the best service and assuring their health and economic security, while emphasizing that our commitment to healthcare flows in both directions.

To this end, we strengthened our health protocols and activated initiatives for proportional protection that enable our customers to offer essential consumer products to our communities. Notably, our digital initiatives—from our omnichannel platforms to our digital route-to-market models—enabled us to maintain frequent contact with our customers while reducing physical exposure, ensuring our clients could remain open for business in a safe and healthy way.

Through the "Mi tienda segura" (My safe store) program, we helped more than 50 thousand of our most vulnerable customers to reopen safely by extending protective measures, promotions and commercial initiatives. Among our initiatives, we displayed COVID-19 Warning Alert Banners on our delivery trucks; we printed 28 million labels with prevention messages; and we delivered 26 thousand protective screens, masks and safety kits to our clients in the traditional trade channel—helping them to keep their doors open and to provide basic consumer goods to families in the region.

Through the "Mi tienda segura" (My safe store) program, we helped more than 50 thousand of our most vulnerable customers to reopen safely by extending protective measures, promotions and commercial initiatives.

Responsible Marketing

At Coca-Cola FEMSA, our consumers are at the center of our decisions and actions. Therefore, transparency, fact-based information, and a high sense of responsibility are the guiding principles for our marketing practices.

To enable our consumers to make healthy informed choices across every one of our operations, our upfront product labels include clear, easy-to-find nutritional content information, including the nutrients, fats, sugar, and sodium in each of our products. Our nutritional labeling strategy is based on providing consumers with clear and complete information in full compliance with applicable regulations in each of the countries we serve. Our aim is to ensure that our consumers are provided with high-quality information; therefore, we are always willing to take part in any regulatory changes. Importantly, during 2020, we adopted a new labeling model and nutrient profile at the request of relevant authorities in Mexico.

As part of our commitment to the wellbeing of our consumers, our advertising adheres to The Coca-Cola Company’s Responsible Marketing Policy and Global School Beverage Guidelines. For instance, as part of the Coca-Cola system, we diligently follow and enforce The Coca-Cola Company’s Responsible Marketing Policy, and we do not market products in channels with an audience predominantly of children under 12. In this and other ways, we underscore our devotion to the healthy habits of our consumers.

Our production processes fulfill the highest quality standards; our ingredients comply with each of our operations’ local regulations and international standards of other regulatory agencies, including CODEX, FDA, JEFCA, and EFSA. Our processes are performed in state-of-the-art bottling facilities within the global beverage industry—all FSSC 22000 certified—thus guaranteeing only the best quality products for our consumers.

Our vision is to develop a fully digital, interconnected, agile, and flexible customer- and consumer-centric platform—deploying capabilities across our commercial, supply chain, finance, and human resources functions.

Commercial

Aligned with our vision, our Commercial Center of Excellence enhances our company’s commercial processes, while strengthening our commercial capabilities:

To further develop our commercial capabilities, over the course of the year, we focused on three digital priorties:

01

advanced commercial analytics platform

02

business-to-business (B2B) and business-to-consumer (B2C) commercial platforms

03

digital trade channel capabilities.

Advanced Commercial Analytics Platform

Already live in Mexico, Colombia, and Brazil, our advanced commercial analytics platform enables our operations to extract greater value by improving their pricing, portfolio, promotion optimization, demand forecasting, and market segmentation capabilities. Moreover, to leverage the insights, skills, and abilities acquired from the development of our commercial analytics platform, we are rolling out internal engines to offer specific capabilities—such as pricing and promotion optimization—to other operations such as Argentina, Costa Rica, and Guatemala. Furthermore, we fully rolled out Victoria, our machine learning prescriptive analytical engine, across our Mexico operations this year, significantly enhancing demand forecast accuracy.

Omnichannel Solution

Consistent with our vision of becoming a digitally driven, interconnected commercial beverage platform, we are accelerating the development and deployment of our customer-centric omnichannel solution, connecting every point of contact in real time—from pre-sellers and contact centers to digital touch points such as direct messaging, web portals, mobile apps, and electronic data interchange (EDI).

To this end, our omnichannel strategy focuses on leveraging state-of-the-art digital enablers to enhance our customers’ experience when they contact and interact with us, intensifying our market presence while taking advantage of real-time fully integrated platforms and information. Currently, we are rolling out three major enablers: an advanced chatbot-enabled order-taking platform that leverages WhatsApp mobile messaging; an e-commerce platform for digital order entry and customer engagement via an app or a web portal; and developing order tracking capabilities. These digital enablers—which are all fully integrated into our transactional system—allow for seamless order taking with an enhanced customer experience and a lower cost to serve. Through these B2B initiatives, we expect to increase sales by expanding customers’ service window to 24/7, improve their value offer and customer experience, while enhancing our efficiency and productivity. To complement our B2B platforms, we designed our direct-to-consumer omnichannel strategy, which we will begin to deploy over the coming year.

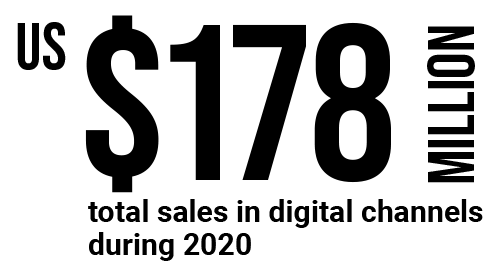

Dynamic Digital Trade Channels

During 2020, we continued to accelerate our first mover advantage across digital trade channels. Capitalizing on our market segmentation capabilities, we put in place agile teams throughout all of our operations to manage, measure, and execute clear strategies for each of these digital customer relationships—from pure players to grocery and food aggregators to e-retailers. Consequently, our company’s gross merchandize value flowing through digital trade channels grew four times or almost 400% year over year, while we continued to win market share and improve commercial execution.

Customer-Centric Route-to-Market Models

This year, we capitalized on our expanding digital capabilities to accelerate the evolution of our customer-centric direct and indirect route-to-market (RTM) models. Through the right combination of direct and indirect RTM models, we continue to improve productivity, maximize customer value creation, and optimize cost to serve.

Harnessing our customer-centric market segmentation, we are scaling and deploying our flexible indirect RTM platform to better serve clients across select territories, sales channels, and beverage categories. Through this platform, we not only prospect and identify the market opportunity, but also pinpoint the right partner, providing them with the appropriate business model and digital (ERP) solution to expand their commercial capabilities. Currently, we are rolling out our indirect RTM platform in Costa Rica, Nicaragua, and Mexico, significantly increasing market reach, improving customer service, and expanding portfolio availability to foster volume growth.

To achieve our vision of becoming a fully digital, interconnected platform, we are merging our digital omnichannel solutions with our physical commercial resources—from pre-sellers to supervisors and call centers—to transform our direct route-to-market models. Through our evolving Commercial Control Tower, we aim to monitor and manage our entire commercial operation, enabling both real-time and dynamic routing. With real-time routing, we adapt our delivery processes—from pre-sellers’ visits to digital apps—to unplanned daily events. For example, our Commercial Control Tower activates “wingman,” a feature that enables pre-sellers to complete a missed visit virtually, allowing us to recover approximately 25% of otherwise lost sales. With dynamic routing, we will design, adjust, and move our commercial resources dynamically, depending on daily, weekly, and monthly market developments.

To achieve our vision of becoming a fully digital, interconnected platform, we are merging our digital omnichannel solutions with our physical commercial resources.

SUPPLY CHAIN

Closely aligned with our company’s strategy and DNA, the supply chain function’s vision focuses on six main pillars:

Aligned with our supply chain vision, we continued to implement our Supply Chain Reinvention initiative to collaboratively and systemically share, adopt, and devise best practices and processes, bolster talent, and capture productivity opportunities throughout our company’s supply chain. As part of this four-year reinvention, we are undertaking end-to-end portfolio analysis and network optimization; maximizing asset utilization and direct material allocation; optimizing primary transportation and load sharing; and designing manufacturing, warehouse, and distribution operations of tomorrow—catering to our business’ future needs.

Digital Distribution

This year, we continued the evolution of our Digital Distribution 2.0 platform with the rollout of real-time routing across 2,900 of our Brazilian operation’s secondary distribution routes, serving 38,000 clients per day. With real-time routing, we adapt our delivery process to unplanned daily events—constantly integrating and analyzing traffic, road, climate, and other conditions—to define the most efficient delivery sequence and route, thereby fulfilling our sales promise while improving customer service and engagement.

Aligned with our omnichannel strategy, we developed our order-tracking platform to enable customers to track their orders created on any commercial channel from the moment of shipment to delivery. Already deployed in Brazil and Argentina, we plan to develop this digital tool for our other operations over the coming year.

Building on its successful deployment in Brazil and Mexico, we implemented our Digital Distribution 1.0 platform, including a web-based app, mobile delivery devices, and vehicle telemetry equipment, across our Colombia, Panama, and Uruguay operations during 2020. Moving forward, we will continue our evolving digital distribution journey throughout our operations.

Warehouse Optimization & Digitalization

During the year, we completed the design of our new Warehouse Operating Model in collaboration with our operations. This model aims to guarantee and continuously improve warehouse service, productivity, and safety levels through the standardization and replication of best operating practices. Within this model, we further defined the key competencies for our warehouse teams’ professional development, aligned with KOF DNA.

Moreover, we continued the digital transformation of our warehouses with the systematic deployment of real and optimal picking. Utilizing voice and digital images, these technological enablers improve our warehouses’ level of service through the assertive assembly of mixed pallets according to client’s specific needs, maximizing load and route optimization while increasing productivity. During 2020, we integrated real picking across 100% of our Brazilian operating units, and rolled out optimal picking to seven operating units.

During 2020, we integrated real picking across 100% of our Brazilian operating units, and rolled out optimal picking to seven operating units.

Talent Development

Furthermore, we are reinforcing the right talent pipeline at the operational level, including a growing pool of manufacturing, distribution, and logistics managers. To this end, we worked closely with our human resources function to establish KLS Academy, a standardized learning platform designed to assure we possess the right technical competencies and functional capabilities across our operations. To complement KLS University, we are also developing functional Distribution, Manufacturing, Warehouse, and Engineering Academies to standardize and develop core capabilities, improve performance, and ensure operational excellence for years to come.

Finance

The ambition of our digitally driven Finance Operating Model is to serve as a business partner to our operations by delivering valuable insights for better and faster decision-making to maximize shareholder value, while ensuring compliance and transactional efficiency. To achieve this ambition, our priorities are to:

Maximize our return on invested capital (ROIC) and shareholder value creation through disciplined capital allocation, working capital optimization, and profitability insights.

Co-design business strategies and support our operations by delivering valuable insights for better and faster decision-making to maximize shareholder value, while ensuring compliance and transactional efficiency.

Proactively manage risks by designing our internal control system and actively address financial, legal, and cyber-security risks.

Prioritize efficiency for all of our transactional activities by boosting penetration and adoption of shared services and digital solutions.

Ensure accuracy of our financial information and compliance with statutory obligations.

This year, we continued to improve our company’s ROIC and shareholder value creation through proactive cost and expense containment, working capital optimization, and disciplined capital allocation. Notably, our implementation of cash control towers enabled us to not only improve cash from operations by 12% year over year, driven by cost and expense controls, but also monitor and enhance working capital management. These towers deliver greater clarity to every single operation on their financial needs on a rolling basis for a period of 13 weeks. We further leveraged our disciplined approach to capital allocation, working hand in hand with operators to reprioritize capital expenditures (CAPEX) while ensuring investments in key projects across our operations.

Importantly, we reinforced our role as a business partner to our operations over the course of this challenging year. Among our actions, we supported our operations by taking the lead in driving cost and expense savings, including significant savings from route-to-market initiatives, non-core labor costs, and efficient marketing expense and discount allocation. We acted quickly to tap the international capital markets before, during, and after the pandemic hit. In fact, thanks to our proactive debt-refinancing strategies, we extended the average life of our debt from seven to nine years, leaving our company with a comfortable debt maturity profile for the coming years. Furthermore, we maintained capital investment in key projects—from improvements to manufacturing plants and warehouse facilities to the launch of new distribution centers to the installation of returnable production lines and labelers. In this way, we worked to ensure operating continuity and product supply, expand our affordable returnable portfolio, and accelerate the rollout of transformational initiatives across our operations.

Moreover, to proactively manage our company’s risks, we are currently upgrading and redesigning our internal control system. As part of this initiative, we are implementing digitally enabled controls to not only monitor, but also actively address financial, legal, and cyber-security risks.

Over the course of the year, we further accelerated the development of our digitally driven Finance Operating Model. Among our initiatives, we are transitioning to a more agile and adaptable cloud-based budgeting platform. Enabled by our digital planning tool, we are working closely with our operations to develop a robust online platform to facilitate financial planning, analysis, and forecasts for every country. Powered by our cloud-based software solution, we are implementing a platform to administer not only our company’s CAPEX projects, but also our strategic operational expense initiatives—expediting authorization processes, sharing best practices, and delivering valuable insights for most of our operations’ investment projects. Furthermore, aligned with our initiative to redefine our process architecture, we are utilizing a range of digital tools to streamline, optimize, and integrate key financial processes—from agile record-to-report to unified order-to-cash processes.

Finally, we continued to deploy our shared financial services strategy, centralizing and consolidating our operations’ transactional activities, such as data processing and reporting, within KOF Global Business Services (GBS) platform. During the year, we expanded the scale and reach of our GBS platform, integrating our Guatemala, Costa Rica, and Panama operations.

Moreover, to proactively manage our company’s risks, we are currently upgrading and redesigning our internal control system. As part of this initiative, we are implementing digitally enabled controls to not only monitor, but also actively address financial, legal, and cyber-security risks.

HUMAN RESOURCES

As a part of our multi-year cultural transformation journey, during 2019, we defined the vision for our Human Resources (HR) organizational model:

Aligned with this vision, we support our business growth by leading cultural change, developing the best talent, and continuing on our path to digital—accelerating the development of automated HR platforms and processes, while always prioritizing employee experience.

Attract and develop the best talent

Ensure our talent becomes the competitive advantage to achieve our company’s strategic goals

Enable our organizational capabilities

Adapt our company’s organizational capabilities to meet evolving business needs

Accelerate HR process standardization and automation

Promote HR processes automation to deliver faster and better services

Path TO DIGITAL

Global Talent Platform

Enhance talent visibility and performance management

Continued deployment of this platform to integrate, improve, and simplify leader and employee experience

Employee central

Transform personnel administration management

Completed implementation of this tool to promote leader empowerment and improve employee experience

hr process

Standardization & Automation

Third Parties Management, Time & Attendance, and Variable Compensation

Simplification, standardization, and selection of automation tool

CYBERSECURITY & INFORMATION SECURITY

The purpose of our Cybersecurity function is to enable a secure and sustainable business. This entails the challenge of strengthening security in the existing infrastructure and systems and implementing security in the digital transformation initiatives. Our vision is to add value by protecting information and our business continuity.

To address this, we have set the following strategic objectives:

Support digital transformation, embedding security by design.

Build a strong cybersecurity culture in the organization.

Build resilience to cybersecurity incidents.

Reach a cybersecurity level consistent with our industry and our business risks.

Enable secure ways of working, appropriate to the post-COVID-19 reality..

Our strategy is built on:

A proper governance model, with a CISO (Chief Information Security Officer) reporting to the CFO and the Audit Committee of the Board, while cybersecurity operations report to our newly appointed CIO.

A cybersecurity framework based on international standards and the periodic assessments conducted by independent cybersecurity experts.

All of these elements, complemented with our team's expertise and technical skills, allow us to have a cybersecurity strategy for the short- and medium-term. During 2020, we implemented several initiatives that have impacted technology, processes, and people, including those to strengthen identity and access management, infrastructure protection, cloud security, internal policies and compliance, data protection and privacy, risk management, and incident response capabilities.

With this approach and keeping up to date with the evolution of the threat environment, we seek to meet the aforementioned objectives in the middle term.

We are aligning to and collaborating with The Coca-Cola Company’s cybersecurity requirements for the system to provide an additional compliance frame of reference for continuous improvement.

As an enabler of our company’s strategic growth, we ensure sustainability is fully integrated throughout our day-to-day decision-making processes and business operations. With the long-term sustainability of our business in mind, we strategically, proactively, and responsibly address our operations’ sustainability challenges across our value chain—from climate change to clean energy, water stewardship, waste management, community development, and safety.

CLIMATE ACTION

Climate change is a strategic risk that we manage through our new 2030 Emissions Reduction Plan. This strategy is designed to drive positive environmental change across the entire value chain—from suppliers to our operations, customers, and consumers.

In order to become a low-carbon company, we adopted the Science Based Targets initiative (SBTi) approach, aligned with the goal of the 2015 Paris Agreement to limit global warming at well below 2°C above pre-industrial levels. Consequently, in 2020, we became the first Mexican company and the third in Latin America to achieve the official approval of our emissions reduction targets by the SBTi. Through this companywide effort, we measured and accounted for the carbon footprint of our entire value chain and adopted science-based targets for emissions reduction that reflect our commitment to a low-carbon economy. Accordingly, our new 2030 commitments (compared with a 2015 baseline) are to:

Reduce absolute scope 1 and 2 greenhouse gas (GHG) emissions from our operations by 50%

Reduce absolute scope 3 GHG emissions from the value chain (covering purchased goods and services and upstream transportation and distribution) by 20%

Achieve 100% renewable electricity for our operations.

Importantly, our absolute emissions targets decouple business growth from GHG emissions. We thereby ensure that, no matter the overall size of our business in 2030, we will make our operations, along with the entire value chain, less carbon intensive than our 2015 baseline.

We are the first Mexican Company to achieve the official approval our 2030 emissions reduction goals by the Science Based Targets initiative.

* We report the carbon footprint of our value chain a year behind, since the inventory is made after the operating year is completed.

CLEAN ENERGY in our OPERATIONS

We strive for energy efficiency across our value chain. We further integrate clean and renewable sources of energy and technologies to reduce our GHG emissions—thus contributing to climate change mitigation. Our operations’ energy consumption focuses on a comprehensive strategy that encompasses our value chain.

At the end of 2020, we achieved our target of supplying 85% of the energy we use for our manufacturing in Mexico from clean sources, with eight months above this threshold, and a 96% use of our Mexican clean energy by the end of the year. Beyond this goal, we supplied 80% of our global bottling operations’ electricity requirements with clean energy sources. We further updated our commitment to reduce the carbon footprint of our value chain aligned with our Climate Action Strategy, and we used clean sources of energy for our manufacturing operations in Argentina, Brazil, Colombia, Costa Rica, Guatemala, Mexico, and Panama.

clean energy

Energy Efficiency, Clean Energy & Emissions Reduction

We aim to improve the energy efficiency of our manufacturing operations, while simultaneously reducing our GHG emissions.

We managed to increase our energy efficiency by 1.52x from 2010 to 2020.

liters of beverage produced per mj

To improve our plants’ efficiency, we have implemented multiple strategic initiatives:

Energy Training – We provide annual energy training to all of our energy managers in every division, as well as all of the operators of each of our work centers.

Energy Assessments – We conduct annual energy assessments to support our operations in Argentina, Brazil, Central America, Colombia, and Mexico.

Steam Standard – We focus on the utilization of steam produced in our plants to reduce consumption, ensure safe use, recover steam condensate, and increase the life of our assets.

Top 20 Energy Efficiency Strategies – We implement key energy efficiency strategies to minimize each of our plants’ energy consumption.

From 2015 through 2020, we achieved a 17.2% decrease in our manufacturing operations CO2 emissions, reaching 13.2 grams of CO2 per liter of beverage produced in 2020.

$1.67

saved as a result of our Clean Energy initiatives

WATER STEWARDSHIP

Water is an essential ingredient in the production of our beverages. Therefore, we are committed to ensuring the efficient use of this natural resource in our bottling operations and returning to our communities and the environment the same amount of water used in our beverages, while safeguarding this resource not only for the benefit of our company, but also for the enjoyment of our communities and planet now and into the future.

From 2010 to 2020, we significantly improved our water use ratio by an impressive 24% to reach an average of 1.49 liters of water per liter of beverage produced, while decreasing our absolute water consumption by 30.6%. We further give back to our communities and the environment more than 100% of the water we use in the production of our beverages in Argentina, Brazil, Central America, Colombia, and Mexico.

Consistent with this commitment, we have established a comprehensive water strategy, founded on three pillars:

Water Efficiency

As a beverage bottler, efficient water management is essential to our business, communities, and planet. At the end of 2020, we reached our goal of averaging 1.5 liters of water per liter of beverage produced with a year-end water use ratio of 1.49 —an impressive 24% improvement in our water use ratio from our 2010 baseline year. Notably, this represented savings of more than 17 billion liters from 2010 through 2020. Moreover, our water efficiency initiatives and projects generated savings of US$1.16 million in 2020.

Through our Top 20 Water Saving Initiatives program, we foster efficient water consumption across all of our plants. To this end, we registered significant progress across our operations, focusing on 20 key measures—from our detection and elimination of leaks to optimal water use in our plants to our water recovery systems. Additionally, all of our manufacturing facilities are ISO 14001 certified.

100% of the water we discharge from our manufacturing operations is sent to wastewater treatment plants, which ensure sufficient quality to foster aquatic life.

According to the World Water Council, 77 million people in Latin America lack access to safe water, and 100 million people lack access to basic sanitation services.

Consequently, in collaboration with FEMSA Foundation, we carry out projects designed to improve communities’ quality of life by helping to provide them with safe water, improved sanitation, and hygiene education. While the Foundation intervenes significantly at the outset of each project, all of these initiatives utilize the necessary elements to enable communities to adopt them in a sustainable way—enduring over the long term.

water efficiency

Liters of water per liter of beverage produced

(less is better)

For more information about FEMSA Foundation, visit https://www.femsa.com/en/femsa-foundation/

Water Replenishment & Conservation

Aligned with the United Nations’ Sustainable Development Goals, we recognize that water is an important and essential natural resource. Accordingly, we join efforts to provide access to potable and affordable water, as well as to protect and recover water-related ecosystems.

Our aspiration is to return to the environment and our communities the same amount of water used to produce our beverages where it matters the most. Aligned with this goal, we currently give back to the environment more than 100% of the water we use in the production of our beverages in Argentina, Brazil, Central America, Colombia, and Mexico.

Given the substantial scope, importance, and complexity of water conservation and replenishment, we further work to strengthen water funds and conserve water basins through sustainable initiatives involving partnerships with multiple stakeholders. Through the Latin American Water Funds Partnership—comprised of The Nature Conservancy (TNC), FEMSA Foundation, the Inter-American Development Bank (IDB), and the Global Environment Facility (GEF)—we jointly seek to achieve and sustain water security in the region, ensuring sustainable access to a sufficient quantity and quality of water to sustain human life and socioeconomic development.

In coordination with the Partnership, we launched the new Cauce Bajío water fund for the state of Guanajuato, Mexico, during 2020. To date, the Partnership has developed 27 water funds. Of these funds, 6 are in countries where we operate—Brazil, Colombia, Costa Rica, Guatemala, and Mexico. As a result, through 2020, the Partnership has worked to directly benefit approximately 215,512 people in areas near the water basins through job creation and capabilities training since the projects began.

We launched the Cauce Bajío water fund for the state of Guanajuato, Mexico, during 2020.

WASTE & RECYCLING

At Coca-Cola FEMSA, we strive to mitigate the environmental impact of our operations’ processes. Over the past several years, we have led the way in the promotion of a culture of waste management throughout all of our operations and value chain.

In 2020, we used an average of 29% recycled content in our PET packaging, exceeding our 2020 goal of 25%. Moreover, by the end of 2020, 100% of our bottling plants successfully achieved our 2020 goal of recycling at least 90% of the waste generated at each of their plants with a global average of 98% of proper waste recycling and disposal.

Consistent with our long-term commitment to waste management and aligned with The Coca-Cola Company’s commitment to a “World Without Waste,” our new 2030 goals are to:

Use at least 50% recycled material in our PET packaging

Make all consumer packaging 100% recyclable by 2025

Collect the equivalent of 100% of the PET bottles we place in the market

Grow participation in marine litter prevention programs and beach cleanups

At Coca-Cola FEMSA, we are confident that, with the support and co-responsibility of all of the actors in the value chain, we will fulfill our 2030 goal of collecting 100% of the PET bottles we place in the market through a concerted market-based approach to the circular economy.

KOF Waste Management Strategy

Comprehensive and responsible post-industrial waste management

Post-consumption collection and recycling

Efficient design and integration of recycled materials in our packaging

Innovative Packaging Development

Within the beverage industry, our product packaging is mainly comprised of polyethylene terephthalate (PET), glass, and aluminum. We are committed to efficiently using our packaging materials; redesigning our packaging’s components to achieve recyclability, while including a growing share of recycled content.

In 2020, we used an average of 29% recycled content in our PET packaging, exceeding our 2020 goal of 25%. Moving forward, we aim to expand this goal to include 50% of recycled materials in our PET packaging by 2030. Notably, we now provide customers and consumers with a water bottle made of 100% recycled resin for all one-way PET presentations of Brisa brand water in Colombia, Ciel brand water in Mexico, Brazil, Crystal brand water in Brazil, and Vitale brand water in Uruguay. Moreover, we successfully launched our universal returnable bottle in Argentina, Colombia, Mexico, and Uruguay.

Consistent with efficient resource management and optimization of packaging materials, we continued to deploy a wide-ranging light-weighting strategy for our operations’ PET presentations and caps. Thanks to our efficient resource management and packaging optimization, we generated savings of approximately US$2.2 million in 2020.

% Recycled Content

In 2020, we utilized a total of 73,000 tons of recycled materials in our operations in Argentina, Brazil, Central America, Colombia, Uruguay, and Mexico. As a result of these efforts, we avoided the use of more than 400 thousand tons of virgin resin since 2010.

Post-Consumption Collection & Recycling

By joining efforts, we multiply the effects of our actions. Accordingly, we partner with communities, authorities, and NGOs on different initiatives to raise awareness of post-consumer waste management, carry out collection and recycling programs within our communities, and inform consumers about the proper disposal and handling of the waste generated from our products, including marine litter prevention, debris collection, and beach cleanups.

Continuing our long-term commitment to collectively address the challenge of waste management and aligned with The Coca-Cola Company’s commitment to a “World Without Waste,” in the main markets in which we operate—Mexico and Brazil—packaging collection and recycling mechanisms account for more than 50% of the PET bottles that we sell, putting us well on track to our 2030 goal of collecting 100% of the PET bottles we place in the market.

Since 2002, we have collaborated with other food and beverage companies through ECOCE, a Mexican civil association that promotes the collection of waste, the creation of a national market for recycling, and the development of recycling programs. With an impressive national collection rate of 53% in Mexico under the ECOCE model, we are at the top of collection and recycling practices in Latin America through this collaboration, with levels equivalent to the European Union.

Across Latin America, we continued to strengthen our post-consumption collection and recycling capabilities. Through SustentaPET, a joint venture created in partnership with The Coca-Cola Company, we launched new PET collection centers in Cosmópolis on top of an existing collection center in Sao Paulo, Brazil. In Colombia, we expanded the MovimientoRE program, an industry alliance to increase PET collection rates, from the cities of Cartagena, Santa Marta, and Barranquilla to Cali through “Cali Circular.” In Argentina, we continued to coordinate our collection and recycling with the industry through CADIBSA, while signing an agreement with the city of Buenos Aires to improve recycling. In Uruguay, we have an industry agreement with Crystal PET to close the PET recycling loop through the use of recycled resin. Furthermore, in Central America, we gained traction with partnerships in Guatemala with “Recíclalos;” in Costa Rica, through Misión Planeta, we partnered with Geocycle to significantly scale PET collection and recycling; and in Panama, through “Recycle for Your Future” (Recicla por tu Futuro), we participate in an industry agreement to foster environmental awareness on recycling.

Importantly, we are leaders in PET bottle-to-bottle recycling in Latin America. In 2005, we joined efforts in Mexico to operate the first food-grade PET recycling plant in Latin America, called IMER (Industria Mexicana de Reciclaje or Mexican Recycling Industry). In 2020, this plant recycled 13,000 tons of PET. Overall, we have a total of 9 recycled food-grade resin suppliers across our operations network.

Post-Industrial Operating Waste Management

In 2020, two thirds of our 49 bottling plants earned Zero Waste to landfill certification. Originally designed for our Mexico operations, this initiative establishes specific measures to improve waste management, disposal, and repurposing—resulting in improved waste efficiency per liter of beverage produced.

At the end of 2020, 100% of our bottling plants successfully achieved our 2020 goal of recycling at least 90% of the waste generated at each of their plants. Overall, we recycled 98% or approximately 110,289 tons of manufacturing waste generated.

Currently, 18 of our plants in Mexico have obtained Clean Industry certification from the Federal Environmental Protection Agency (PROFEPA). Moreover, in 2020, 36 of our distribution centers in Mexico received air quality certifications from PROFEPA, the state of Mexico’s Environmental Agency, and Mexico City’s Ministry Secretary of the Environment (SEDEMA). These and other recognitions confirm our commitment to the environment and overall sustainability.

To this end, we diligently work to ensure our processes comply with the highest national and international standards and with all applicable laws, avoiding sanctions and fines pertaining to environmental issues, while reaffirming our commitment to efficient operational processes, environmental performance, and competitiveness.

waste efficiency

grams of waste per liter of beverage produced (Less is better)

ENVIRONMENTAL Performance

The following table concentrates the historical performance of our most important environmental indicators.

| Performance Indicator | Unit of Measure | 2015 | 2016 | 2017 | 2018* | 2019 | 2020 |

|---|---|---|---|---|---|---|---|

| Beverage produced | Billion liters | 21.2 | 21.0 | 20.3 | 19.7 | 18.6 | 18.3 |

| Water use1 | Billion liters | 37.5 | 36.0 | 33.4 | 31.3 | 28.2 | 27.1 |

| Water efficiency | Liters of water used per liter of beverage produced | 1.77 | 1.72 | 1.65 | 1.58 | 1.52 | 1.49 |

| Total PET used | Thousand tonnes | 338.3 | 296.1 | 281.2 | 317.2 | 268.9 | 249.2 |

| PET virgin resin used | Thousand tonnes | 288.9 | 248.7 | 221.7 | 253.3 | 205.2 | 176.2 |

| Recycled PET use | Thousand tonnes | 33.7 | 47.4 | 59.5 | 63.9 | 63.6 | 73.0 |

| Recycled materials used in PET packaging | Percentage of total PET used | 14.6% | 20% | 21% | 21% | 24% | 29% |

| Waste generated | Thousand tonnes | 174.0 | 174.0 | 152.0 | 135.4 | 119.1 | 112.5 |

| Waste recycled | Thousand tonnes | 164.0 | 163.0 | 144.0 | 132.4 | 114.0 | 110.3 |

| Waste recycled | Percentage of total waste generated | 94% | 93% | 94% | 98% | 96% | 98% |

| Waste efficiency | Grams of waste generated per liter of beverage produced | 8.2 | 8.3 | 7.5 | 6.9 | 6.4 | 6.2 |

| Total energy use2 | Million Megajoules | 5048.0 | 4862.0 | 4514.0 | 3858.9 | 3399.4 | 3253.0 |

| Energy from fuel use | Million Megajoules | - | - | 2382.0 | 1872.5 | 1615.8 | 1581.2 |

| Electricity from clean sources | Million Megajoules | - | - | 810.2 | 1024.4 | 1260.8 | 1365.7 |

| Other electricity | Million Megajoules | - | - | 1321.8 | 962.1 | 522.8 | 306.1 |

| Energy efficiency2 | Liters of beverage produced per Megajoule of energy used | 4.2 | 4.4 | 4.5 | 5.1 | 5.5 | 5.6 |

| Global clean energy use | Percentage of total energy use | 19% | 29% | 38% | 51.6% | 70.7% | 80% |

| Clean energy use in Mexico | Percentage of total energy use | 30% | 46% | 57% | 51% | 69% | 85% |

| Absolute Greenhouse Gas Emissions3,4 | Thousand CO2e | 292.3 | 265.0 | 247.4 | 262.6 | 255.4 | 242.1 |

SAFETY COMMITMENT

Safety is a key priority, a basic principle of action, and a fundamental value for our company; it is of the utmost importance to fulfilling our purpose of always finding the most efficient and sustainable way to put the drink of choice in our consumers’ hands anytime, anywhere. That is why we are committed to do everything within our control to ensure the wellbeing of our employees, contractors, and the communities we serve in order to achieve our ambition of zero work-related injuries and illnesses—based on the premise that all incidents are preventable.

Aligned with our 0.0 Safety Vision, our 2025 goals are to reach:

Zero fatalities

Lost Time Incident Rate (LTIR) of 0.4 for employees and contractors

Total Incident Rate (TIR) of 0.8 for employees and contractors

Crash Rate of 6.5 for employees and contractors

Safety Performance

Our 2020 safety performance showed significant progress on several important fronts. For the year, we reported a Lost Time Incident Rate (LTIR) of 0.74 in 2020, a 32% reduction from 2019 and a 58% reduction from 2016. Notably, our manufacturing operations in Argentina, Brazil, Costa Rica, Guatemala, and Mexico already achieved an LTIR of 0.5 or below. We also achieved a Total Incident Rate (TIR) of 1.33, a 29% reduction from 2019. We further achieved a Crash Rate of 11.32 and a Major Crash Rate of 1.92, reductions of 34% and 63%, respectively, from 2019.

Lost Time Incident Rate-LTIR1

(Less is better)

Total Incident Rate-TIR2

(Less is better)

(# Accidents x 200,000)/Hours Worked.

(# Total Reportable Incidents x 200,000)/Hours Worked.

Safety Strategy

This year, we defined our 0.0 Safety Strategy, including the challenge ahead and the three main initiatives that will enable us to accomplish the goals of our 2020 – 2023 vision.

0.0 SAFETY STRATEGY initiatives

0.0 RTM

Safety

Rapidly reduce road incidents and fatalities through risk management, capabilities development and management protocols, and cultural change around road safety and safe mobility with the implementation of technological enablers to ensure our Strategic Road Safety Plan within the distribution, logistics, and commercial processes

Safety of Third Parties

and Contractors

Develop, implement, and integrate our Safety Strategy, requirements, and commitments with contractors and other third parties, making these relationships sustainable

Prevention of Serious

Injuries and Fatalities (SIF)

Ensure ZERO FATALITIES and reduce serious injuries through incident management and systemic integration of management, culture, processes, capabilities, and technology

The Challenge: Ensure the integrity of our people and the people who interact with our operations, influencing our organizational culture, enabling business growth, and maintaining a leadership position within the Coca-Cola system and the beverage industry.

To design and implement our 0.0 Safety Strategy, we launched three Safety Collaboration Communities—one for each strategic initiative—with the participation of over 40 key employees from across our operations.

kof safety qse communities

Our approach to safety is focused on collective and individual accountability, as reflected in the five key elements of our Safety Accountability Model.

Safety Accountability Model

Safety Culture

This year, our Safety Cultural Transformation played a fundamental role in our operations’ ability to face the COVID-19 pandemic—from their emphasis on self-care to their reinforcement of safe habits, beliefs, and behaviors. During 2020, our transformational teams created COVID Watchers, who were responsible for promoting and enforcing safe habits and behaviors aligned with COVID-19 safety protocols. We extended the reach of our behavior-based safety approach to cover COVID-19 pandemic recommendations. We also broadened our cultural approach to factor in psychological safety, a powerful element that ensures sustainability, collaboration, and trust.

Safety Technology & Digitalization

Our safety technology and digitalization pipeline continues to enable our Road Safety Strategy and results. Based on three key elements—People, Organization, and Vehicles—this strategy has enabled us to significantly improve road safety by reducing the number of accidents within the organization. To support this strategy, our business units have continued to implement initiatives and innovations that have accelerated the positive performance in this critical area, focusing on the development of drivers’ capabilities and the implementation of technology for road risk monitoring and management. During 2020, we developed and deployed the following key initiatives:

Focused on vehicle operation, functional assignments, speed and space management, decision-making, preventive and defensive management, adverse conditions, emergency maneuvers, work methods and controls, and alcohol and drug management.

All drivers’ performance is continually monitored and managed through telemetry equipment installed on each truck, along with support videos, a disciplinary process, and a recognition program to encourage road incident prevention and mitigation.

Virtual reality simulator offered training and capacities evaluation for safe handling of these operations’ distribution vehicles and forklifts.

Focused on defensive and preventive driving, road accident reduction, vehicle wear and tear, and fuel consumption across this operation’s primary and secondary distribution fleet.

Installed forklift telemetry to identify, monitor, and manage behaviors and drivers.

Aligned with best corporate and Colombian road safety standards, this strategy is focused on the five key elements of institutional management, human behavior, safe vehicle, safe infrastructure, and attention to victims.

Integrated driver assistance systems, designed to reduce accident rates, monitor driving habits, and redefine working hours management based on profiles of each operator across the primary distribution fleet.

Developed and piloted TTT technology in 20 secondary fleet distribution units to prevent and reduce the five main causes of road accidents.

Thanks to these and other transformational initiatives, we achieved a 33% crash rate reduction compared with 2019.

Serious Injuries and Fatalities Management

During the year, we launched phase three of our corporate safety standards for the prevention of fatalities. Thanks to these standards, 2020 was the first year that we achieved zero fatalities within our manufacturing facilities and distribution centers.

Consistent with our commitment to incident prevention, we designed and implemented our Serious Injuries and Fatalities (SIF) Management Model, composed of four key elements:

Safety protocols standardization

Safety incidents escalation and exposure matrix

Key performance indicator (KPI) monitoring with a technological enabler

Life Saving Rules, developed in collaboration with the Coca-Cola system

life saving rules

Commitment to Zero Fatalities

Aligned with our 0.0 Safety Strategy, we continually research, analyze, and identify the measures required to reduce the number of injuries resulting from our operations. Despite our best efforts, we regret to report an increased number of fatalities during 2020 compared to the preceding year.

For the year, we reported a total of 31 fatalities, 94% from road accidents and 6% from public safety conditions within the countries in which we operate. Although 95% of our operations reported no fatalities, the remaining 5% is still an unacceptable number. We will not be satisfied until we fulfill our promise and commitment to zero incidents. We offer our condolences to the families and people affected by our operations, and we pledge to implement best practices to prevent any future losses.

Total Fatalities

Own employees + third parties + communities

SUSTAINABLE MOBILITY

Through our Sustainable Mobility strategy, we aim to reduce the impact of our fleet—including primary and secondary distribution trucks—and to position ourselves as the industry leader in Latin America in terms of vehicle efficiency, environmental stewardship, and safety.

We continued to execute route optimization strategies to maximize overall vehicle efficiency. With the deployment of KOF Digital Distribution 1.0 platform in Brazil, Colombia, Mexico, Panama, and Uruguay, we installed vehicle telemetry equipment on 100% of these operations’ secondary distribution fleet. Thanks to each truck’s telemetry data—together with the functionality of our mobile delivery devices—we enjoy the ability to identify and correct deviations in distribution route execution versus our route plan. This equipment also enables us to analyze route execution patterns in order to identify an optimal combination of variables to improve our route planning process. As a result, we optimize our fleet’s usage, minimizing vehicles’ downtime while maximizing vehicles’ uptime. Thanks to our telemetry equipment, we not only improved key road safety indicators, but also reduced fuel consumption while decreasing CO2 emissions.

Moreover, with the deployment of dynamic routing across our secondary distribution fleet in Brazil and Colombia, we enjoy the flexibility to plan vehicles’ routes on a daily, weekly, and monthly basis, thereby optimizing available fleet resources and distances traveled to serve our customers.

Additionally, we leveraged our secondary fleet substitution program in Mexico and Brazil, where we maintain the largest volume of delivery trucks. Over the past five years, we have substituted we have substituted our fleet with vehicles that meet higher standards to reduce emissions. Thanks to this program, we reduced our fuel consumption, emissions, and maintenance costs, and we reinforced our commitment to eco-efficiency with local environmental authorities.

Through our self-regulation program in the Valley of Mexico, we commit to minimize the local delivery fleet’s emissions through key initiatives, including an efficient maintenance process and ongoing fleet substitution program, fostering our social license to operate.

In recognition of our efforts to reduce our primary and secondary fleet’s emissions, we earned the Clean Transportation Award from Mexico’s ministries of Environment and Natural Resources (SEMARNAT) and Communications and Transportation (SCT) for the ninth year.

SHARED OPPORTUNITY

WITH OUR COMMUNITIES

We work to strengthen and consolidate positive relationships with the communities with which we interact. We identify and develop shared opportunities for our company and communities’ sustainable development, enhancing our ability to serve the marketplace while maintaining our social license to operate.

Sustainable

Sourcing

At Coca-Cola FEMSA, we work with our suppliers to reduce the environmental and social impacts generated by our commercial interactions and thus improve the conditions of our supply chain. In this way, we not only minimize negative impacts, but also raise standards in key business areas, increase labor efficiency, preserve environmental capital, and reduce risks and costs for all of those involved throughout the value chain.

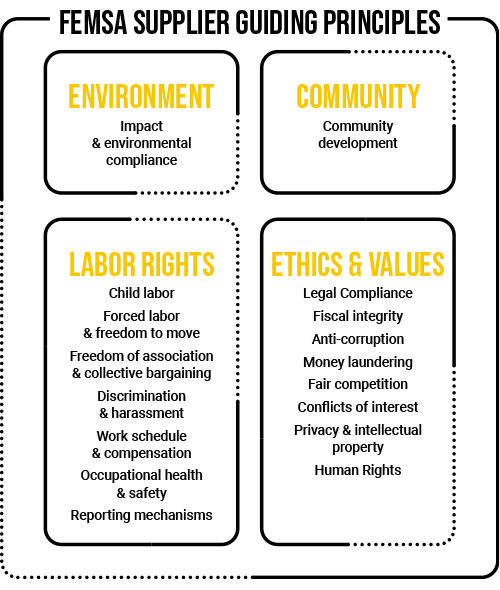

As part of our company’s sustainable sourcing mandate, in conjunction with our defined strategic initiatives, each supplier cooperates to minimize their social and environmental risks over which we have no direct control and which cause the greatest number of impacts throughout our supply chain on a daily basis. The general guidelines that we use to make this happen are:

The Coca-Cola Company’s (TCCC) Supplier Guiding Principles focus on strategic input categories and include areas such as Human Rights Policies, Environmental Protection, and Labor Rights. Through audits that ensure compliance with these standards, TCCC authorizes its bottlers to work with approved suppliers.

Sustainable Agriculture Guiding Principles. Established by TCCC, they include the same areas as the previous principles, but are adapted to suppliers of agricultural raw materials.

FEMSA’s Supplier Guiding Principles. We apply these principles to mitigate social risks of suppliers for categories that are different from those of the strategic inputs and are relevant to the value chain.

These principles reflect the standards that guide our daily activities to ensure we provide responsible workplaces that protect human rights and comply with environmental laws. Founded on these principles, we follow a comprehensive five-step Sustainable Sourcing Strategy:

Prioritization of categories

At Coca-Cola FEMSA, we use a proprietary tool to identify which suppliers are candidates for a development process. Suppliers are prioritized considering factors such as expenditure, environmental, social, and ethical impacts for each product category, dependability, brand association, and operational criticality.

Sustainable purchases

Through this step, we include FEMSA’s Supplier Guiding Principles in our supplier contracts and requests for information, provide general guidelines for assessment procedures, and conduct training for sourcing and purchasing employees.

Assessment

At Coca-Cola FEMSA, we assess our suppliers continuously through our Sustainable Sourcing System, ensuring that they are aligned with our company’s operating principles and values. Carried out online, this assessment focuses on four main areas: Social/Labor Rights; Environment; Ethics and Values; and Community. To ensure the process’ transparency, a third party reviews and verifies the information, and we then provide feedback and create action plans to encourage supplier development, ethics, and sustainability. All suppliers with low scores are subject to improvement plans at their facilities and are evaluated periodically to encourage their continuous improvement. This year, we conducted 619 supplier evaluations based on FEMSA’s Supplier Guiding Principles. Since 2015, we have carried out 2,516 evaluations under these principles.

Consistent with this strategy, The Coca-Cola Company (TCCC) assesses and ensures compliance with its guiding principles and sustainability standards for specific categories of strategic suppliers; at Coca-Cola FEMSA, we only work with suppliers approved by TCCC in those categories. In 2020, TCCC carried out 120 evaluations of suppliers aligned with their Supplier Guiding Principles and Sustainable Agricultural Guiding Principles.

In addition to these assessments, Coca-Cola FEMSA is one of the few companies that promoted the application of these assessments to Tier 2 suppliers or the suppliers of our suppliers. Currently, our strategic suppliers are applying the same risk assessment and mitigation mechanisms within their own value chain. This ensures that the knowledge and the drive for greater sustainability not only remains within our direct circle of influence, but also extends to all of those who participate in supplying raw materials, inputs, and services.

Capabilities development

To strengthen our suppliers’ business capabilities, we provide them with access to training and growth initiatives on topics such as finance, marketing, and human resources, among others. We also support their growth and build their business skills, improve their companies, and develop high quality products aligned with our principles and values.

In collaboration with the Mexican Center for Competitiveness (Centro Mexicano de Competitividad), we carry out a Comprehensive Supplier Development Program for strategically selected small- and medium-sized enterprises (SMEs) to improve their business capabilities. Through this program, we collaborate with suppliers to not only improve their sustainable competitiveness, but also forge stronger relationships with our company and other large companies. In 2020, 19 suppliers participated in the program, training a total of 285 suppliers from Mexico and Costa Rica over the past five years.

Recognition

The good performance of our suppliers on sustainability issues is very important. Accordingly, we recognize all of those suppliers that incorporate sustainability into their own business’s DNA not only as a requirement for doing business with Coca-Cola FEMSA, but also as a competitive advantage and a means to become socially responsible. During 2020, we conducted virtual recognition forums for suppliers to our Brazil, Costa Rica, Guatemala, Mexico, and Panama operations, where we recognized 23 suppliers from over 215 participating companies for their remarkable practices.

During 2020, we collaborated with Redecim to promote our suppliers’ contribution to the UN SDGs. Altogether, 38 companies participated in this effort, committing to specific goals and linking the achievement of these goals to their business success.

The Coca-Cola Company

| COUNTRY | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 |

|---|---|---|---|---|---|---|

|

Mexico |

33 |

52 |

40 |

59 |

37 |

27 |

|

Costa Rica |

2 |

3 |

7 |

0 |

1 |

7 |

|

Guatemala |

3 |

5 |

8 |

7 |

8 |

7 |

|

Nicaragua |

0 |

1 |

0 |

0 |

1 |

1 |

|

Panama |

1 |

0 |

3 |

3 |

2 |

1 |

|

Argentina |

5 |

11 |

19 |

10 |

10 |

10 |

|

Brazil |

54 |

47 |

102 |

51 |

42 |

57 |

|

Colombia |

8 |

7 |

18 |

11 |

4 |

10 |

|

Total |

107 |

126 |

197 |

141 |

105 |

120 |

Coca-Cola FEMSA

| COUNTRY | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 |

|---|---|---|---|---|---|---|

|

Mexico |

100 |

198 |

245 |

172 |

165 |

164 |

|

Costa Rica |

30 |

120 |

106 |

34 |

36 |

35 |

|

Guatemala |

- |

- |

49 |

34 |

36 |

35 |

|

Nicaragua |

- |

84 |

94 |

27 |

21 |

15 |

|

Brazil |

- |

- |

45 |

66 |

63 |

245 |

|

Panama |

- |

- |

- |

36 |

24 |

30 |

|

Argentina |

- |

- |

- |

31 |

31 |

17 |

|

Colombia |

- |

- |

- |

- |

30 |

51 |

|

Uruguay |

- |

- |

- |

- |

15 |

27 |

|

Total |

130 |

402 |

539 |

400 |

426 |

619 |

Sustainable Community Development

Aligned with our comprehensive management framework, this year we prioritized the safety and wellbeing of our employees, customers, consumers, and communities throughout the COVID-19 pandemic. By prioritizing their health and safety, we reinforce our company’s commitment to delivering economic value, while generating social and environmental wellbeing.

As a leading beverage company, we have made our resources available to build on the actions of the communities where we operate. In solidarity with our communities and in collaboration with health professionals at the front line of the COVID-19 health emergency, we have offered our company’s support through our donation of more than 3.85 million liters of beverages to medical centers and vulnerable communities across our markets. We have collaborated with government authorities to leverage our marketing spaces and delivery trucks in the communication of prevention measures. We have teamed up with The Coca-Cola Company and other organizations in the expansion of hospital capacity. We have also joined forces with various institutions, organizations, and industry groups in the distribution of 1.9 million medical supplies.

Among our different community health and safety efforts, we donated more than 26 thousand COVID-19 tests focused on front-line healthcare professionals in Sao Paulo, while teaming up with the sugar cane industry to deliver more than 500 thousand liters of sanitizing alcohol to hospitals in Sao Paulo’s public health network. In Mexico City, we teamed up with The Coca-Cola Company and other organizations in Mexico to convert the Citibanamex Convention Center into a temporary medical facility, which has been operational since late April. In Argentina, we donated more than 325 thousand liters of beverages to at-risk populations in collaboration with NGOs, municipalities, and health institutions, and in Uruguay, we participated in the #NosCuidamosEntreTodos initiative, which has donated funds for medical supplies. Additionally, in Colombia, we donated beverages to the most affected populations in the country through alliances with the national police, the Red Cross, mayors, and food banks, and in Venezuela, we donated water to health centers, shelters, and vulnerable communities. Furthermore, in Central America, we donated more than 150 thousand liters of beverages to the elderly, front-line health professionals, volunteers, and police, while communicating preventive measures through more than 200 distribution routes.

This year, the global, immediate, and simultaneous impact of the COVID-19 pandemic required us to not only further strengthen our Human Resources model, but also to delegate better and trust one another more—assuming full responsibility for our roles with no room for overlapping jobs or functions.

This empowered our senior management team to lead by example and visibly change key roles and behaviors:

Consequently, the evolution of our senior management team’s leadership and decision-making is evident throughout critical stages of our cultural transformation journey.

As we move forward, the vision of our Human Resources (HR) function is to:

Attract and develop the best talent. Ensure that talent becomes our competitive advantage to reach our company’s strategic goals

Enable organizational capabilities. Adapt company’s organizational capabilities to meet evolving business needs

Accelerate HR process standardization and automation. Promote HR process automation to deliver faster and better services

Aligned with our vision, the HR teams act as agents of change—leading our collaborative cultural transformation, developing the best talent, and implementing agile processes at the optimal cost for the organization.

CEO & LEADERSHIP TEAM

Embrace and role model desired behaviors

Work collaboratively to encourage others to do so

Empower direct team

Openly receive feedback and give honest and open feedback

Serve as the driver of our culture

Functional Areas

Provide a service, not serve front-line units

Be responsible for their functions in each country

Have clearly defined roles and responsibilities aligned with the operations

Embrace and role model new ways of working—simplicity, collaboration, agile, lean

Focus on the greater good—we before me

Operations

Drive profitable growth by serving our consumers, customers, and communities

Be responsible for profit and loss (P&L) of operation

Collaborate and work with functional areas

Focus on the greater good—we before me

CULTURAL & ORGANIZATIONAL TRANSFORMATION

In 2018, we began our cultural transformation journey with the launch of KOF DNA to ensure that our customers and consumers are at the center of everything we do. This year, we continued our journey—underscoring that our people and the way they work together are our company’s most valuable assets.

Comprised of five key foundational elements, KOF DNA is the set of core beliefs and behaviors that we aspire to live and breathe each and every day.

Over the course of this challenging year, we brought our “people first” mentality to life through all of the actions we undertook to protect our people’s safety and to ensure operational continuity. Aligned with our DNA, we activated multiple initiatives:

Reinforce hygiene and safety protocols, focused on protecting our people and their families

Adjust management routines and operating processes, centered on ensuring our employees’ and contractors’ wellness

Strengthen remote work schemes in order to support leaders and their teams to maintain productivity and results

Role-modeling visible leadership actions that foster openness and trust among teams

Enhance employee recognition mechanisms, especially among front-line employees who enable us to ensure operating continuity

Foster communication, collaboration, and cohesion through targeted communications to improve work from home schemes

Quickly adapt our business models to serve our markets and people’s changing needs.

We also focused on agile leadership capabilities to face the year’s challenges and to respond to our customers, consumers, and organizational needs.

We complemented our cultural transformation journey with better communication channels for our people, including digital optimization processes. We further continued with the deployment of KOF DNA across all operations and organizational levels, while measuring adoption of desired DNA behaviors through different companywide surveys—which showed higher participation rates than our initial targets at the operational level.

Sustainable development begins with us. Hence, we are committed to offering our more than 80,000 employees safe and dignified environments and workplaces based on respect, equity, transparency, and free participation; the effective implementation of which is essential for the integral development of people, positively affecting their quality of work life.

As part of our transformation process, we updated our Labor & Human Rights Policy, which integrates the Fundamental Principles and Rights at Work of the International Labor Organization (ILO), such as:

Freedom of association

No to forced labor

No to child labor

No to discrimination

No to bullying, violence, and harassment

Security and health at work

In addition, consistent with our cultural evolution, we developed a self-assessment methodology, called “Working Conditions Assessment,” to identify the gaps in our operational basics, work obligations, the needs of our people and how they feel, which we implemented in over 120 work centers of our Mexico operation, representing around 80% of our footprint in Mexico. This evaluation allowed us to gather relevant information about our operations to prevent labor risks, which will help us to materialize our “People First” mentality.

Some of the evaluated concepts are:

Work environment

Immediate supervisor’s management practices

Psychosocial risks

Labor violence and discrimination

Compensation schemes

Child labor

Security and health

Infrastructure and work tools, among others

Furthermore, we continued with the implementation of our functionalized Human Resources organizational model through service and alignment surveys, change agent networks, and new ways of working to identify corporate and operational gaps within and among our functionalized directions and to develop action plans to mitigate those gaps.

TALENT MANAGEMENT AND DEVELOPMENT

Our people and the way they work together are our company’s most valuable assets. Accordingly, we comprehensively manage, attract, develop, and motivate our people effectively, preparing the next generation of leaders today.

This year, we standarized and digitized 100% of the of the development agendas of our Tactical and Strategic Leaders.

Performance, Succession & Mobility

This year, we implemented a functionalized talent cycle across all of our operations; including development agenda planning with a wider and better offering to meet our people’s needs. We also continued to implement our improved performance management model, focused on the value that each individual contributes to the organization and their adoption of our company’s desired DNA behaviors, which represent 30% of our employees’ annual results.

During the year, we further deployed the annual 9-Box Talent Assessment and Management Methodology, enhancing our talent quality, succession, mobility, and execution metrics, while focusing on our high potential talent. During 2020, our employees, from executive, senior, and middle management, as well as individual contributors, were evaluated throughout our operations in order to identify and take actions to develop our talent pipeline within the company.

Moreover, after last year’s launch of our Global Talent Visibility program, we designed programs to achieve higher talent visibility across the organization, while injecting talent through initiatives such as our Young Professionals and accelerated Supply Chain development programs to provide a better talent succession pipeline across key positions. For professionals with at least 18 months of employment experience, our Young Professionals program is designed to attract and develop key talent who could achieve higher positions in our organization within two years. Similarly, our tailor-made, two-year Supply Chain development programs aim to accelerate the development, exposure, and national and international mobility of key talent within the supply chain functional area.

PATH TO DIGITAL

During the year, we continued the deployment of our Global Talent Platform throughout all of our operations. Ultimately impacting 70,800 employees, this platform will integrate, improve, and simplify our leaders’ and employees’ experience with HR processes. Among the year’s developments, FEMSA University migrated to a learning module within our Talent Platform, enabling opportunities for self-learning and development across all of our operations. Currently, we are working on standardizing and migrating our HR Administration backbone, including our master database and payroll systems, to a cloud-based solution in order to provide a more agile service and set the foundation for our path to digital.

This year, we reviewed all of our Data Management processes to ensure the standardized, accurate configuration of our digital enablers, and we began with the implementation of Employee Central, which will impact all of our employees across our operations. This tool is designed to transform personnel administration management, promoting leaders' empowerment while improving our employee experience. We also made major improvements to our basic HR processes, focusing on the simplification, standardization, and automation tools for our variable compensation, which we already deployed in Costa Rica, and time and attendance which we implemented in Brazil.

Training hours

INCLUSION & DIVERSITY

At Coca-Cola FEMSA, we aim to create an environment in which every individual can feel included and valued for their own knowledge, behavior, competencies, and results, with opportunities for development and recognition based on their own talent. To this end, our strategic goals are to:

Aligned with our Inclusion & Diversity Strategy, we developed our diverse talent pipeline strategy to identify female talent within our organization and to design specialized development programs to promote women’s representation in leadership positions. We further undertook multiple initiatives to communicate our overall Inclusion & Diversity Strategy throughout the organization.

Inclusion & Diversity Board

To accelerate the development of a truly inclusive and diverse organizational culture, we evolved from a “networks” approach to a companywide Inclusion and Diversity Board. Aligned with our company’s business priorities, the Inclusion and Diversity Board is focused on five main purposes:

Engage and hold leaders accountable throughout the organization

Define both long- and short-term objectives and strategies aligned with our company’s inclusion and diversity vision

Ensure functionality of work teams at a country and regional level

Ensure deployment of an internal and external communication plan

Measure, monitor, and evaluate initiatives.

To reinforce our company’s commitment to inclusion and diversity, we conducted a range of initiatives throughout the year—from our inaugural “We-talks” conversations to “our label is talent” campaign to our Inclusion and Diversity Forum—enabling our employees to reflect on the importance of inclusion and diversity for our organization, encourage our company’s development of inclusive leadership, and empower managers and directors to strengthen our culture of inclusion and diversity.

Furthering on our Inclusion & Diversity mindset, in Brazil we employed our first fully inclusive production line, operated 100% by professionals with disabilities. We made proper accomodations so people with hearing, physical, visual and learning disabilities enjoy working opportunities in our bottling plant in Bauru.

Employees

Employees

Turnover

Flexible Benefits

We encourage a good work/life balance for our employees. In 2019, we standardized our different flexible benefit schemes across our operations, including:

Flexible schedules

Work from home

Maternity/Paternity leaves

Paid personal days

This year, amidst the COVID-19 pandemic, we promoted flexible benefits policies, activating work from home schemes for all of our administrative teams, while enabling a variety of initiatives to allow our people to work effectively and productively from home, including learning capsules, webinars, videos, follow-up sessions, and virtual town hall meetings.

Taking advantage of telepresence and virtual spaces, we celebrated key management protocols such as our Leaders Summit with great success.

Parental leave

Return Rate per Gender1

Retention Rate per Gender2

1 Employees that returned to work after Parental Leave.

2 Employees that continue working 12 months after Parental Leave.

Male Parental Leave varies in each country from 2 to 14 days.

COMPENSATION AND BENEFITS

Our people’s compensation and benefits scheme not only recognizes their effort and commitment to their jobs, but also their contribution to our company’s value creation. Therefore, despite the challenging scenario posed by the COVID-19 pandemic, during 2020, we were able to keep salaries in line with local levels of inflation or market references.